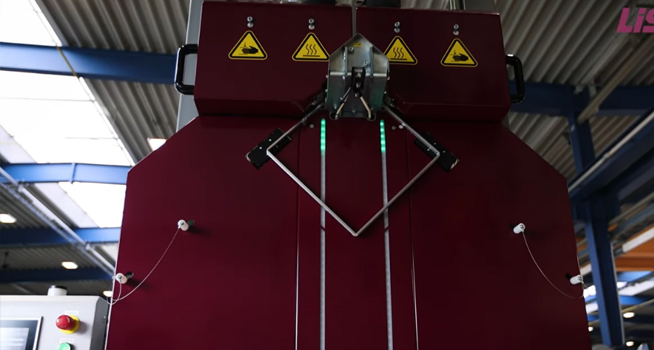

With the desiccant filling machine LiSEC‘s ARL-45F, spacer frames made from all common materials can be filled with desiccant, both as rectangular frames and as shapes. Filling at the back of the frame guarantees a stable process, even with delicate plastic materials. The optional measurement of the desiccant quantity can ensure that there is sufficient desiccant in the frame compared to other systems.

Functions included as standard

- Automatic drilling of the spacer frame on the rear side of the short and long frame leg

- Adjustment of the optimum working height by means of a pneumacatic lifting device

- Automatic pumping of the granulate from a 200 litre drum to the filling devices

- Simultaneous filling of two sides of the spacer frame with granulate

- Sealing the drilled hole with butyl

Functions optionally added

- Measurement and documentation of the desiccant filling quantity

- Equipment for processing heat-flexible spacers (Swisspacer, Multitech, Thermobar, TGI Precision)

- Processing of frames with a maximum size of 3,500 by 1,200 millimetres