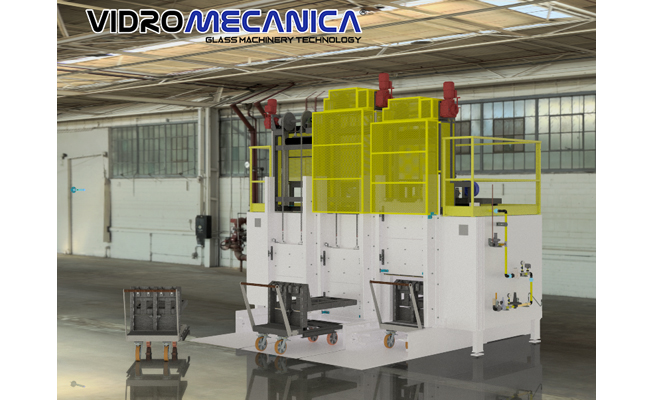

Vidromecanica produces modern mould preheating kilns, adapted to the glass industry demands, furnished with advanced temperature controls and heating systems.

Vidromecanica uses 3 different heating systems, which are chosen according to production demands:

- Gas with direct flame;

- Gas with isolated flame;

- Electrical.

A special design of the inside chamber and recirculation ducts, and the use of a re-circulator with the adequate features to the heating type, are fundamental for an excellent performance of the equipment.

To place the moulds inside there are mould carrier carts with special wheels and charging tables, where the moulds are placed to be heated and withdrawn when they come out of the kiln. The automatic operation of the carts and of the door opening and closing allows for smooth operation and energy saving.

The standard kilns can have up to 4 mould carrier carts and 4 independent doors, that allow placing the moulds by sectors and decrease the energy losses when taking the mould out.

Vidromecanica has developed and improved an oven type in which the carrier cars are mobile and can circulate throughout the manufacturing floor, facilitating the transport of the moulds. This eliminates transfer operations, making the job of operators easier and faster.