Laser marking of metals and plastics has been widely used in industry for some time because permanent marking allows product tracking throughout the production cycle and, ideally, throughout the product’s life cycle. However, this technology hasn’t gained much traction in the glass industry due to the unique challenges glass presents during processing.

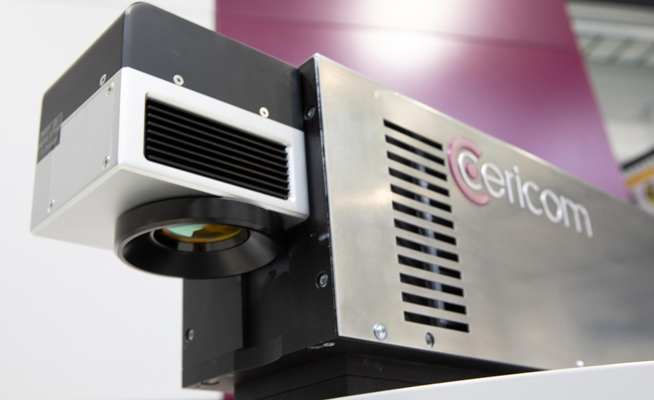

Existing solutions have often provided unsatisfactory quality results or have been costly to purchase and operate. To address this, cericom‘s “c-mark” marking module was introduced in 2023. It can be used wherever high quality marking is required or where intellectual property issues are an issue, such as safety glass marking, automotive, medical, jewelry and perfume industries. c-mark is suitable for both slow and fast production lines, and with the now optional “Marking on the Fly” technology, processing times are significantly reduced.

When glass components need to be tracked and documented in a production cycle, that’s where the laser marker comes in. It can mark directly on the glass without the need for additional materials. With the optional “Marking on the Fly”, this process is exceptionally fast.