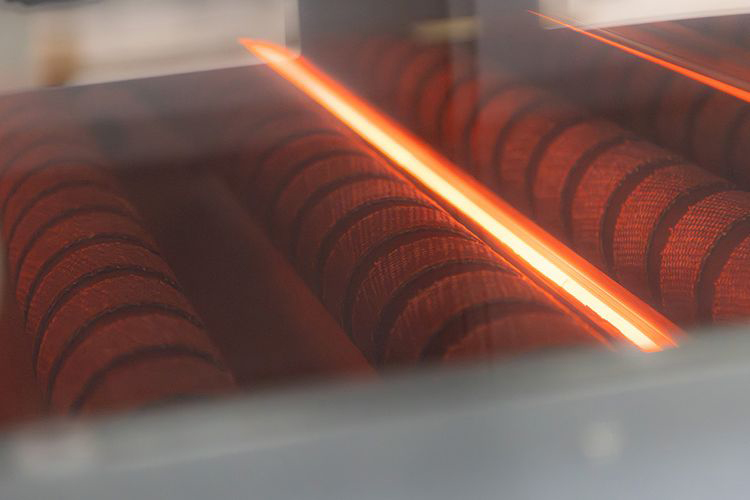

Arbonia Glas in Deggendorf, Germany, manufactures high-quality laminated safety glass made of toughened safety glass, heat-strengthened safety glass and float glass for the interior sector, with rapid delivery times and a high degree of delivery reliability. The company now uses a LiSEC pre-lamination furnace for the final process step – the bonding – which is critical to success: Product quality and energy efficiency.

Matthias Baumgartner, Technical Operations Manager at Arbonia, explained the background to the project: “The idea of replacing the pre-lamination system came about due to the increased energy costs, which are largely incurred in the pre-lamination system in the LSG process. Added to this, our KPI is speedy delivery. Because the LSG process is the last step, it is particularly critical; the glass has already been cut, drilled, contains cut-outs and countersinks and is toughened at this point – we are talking about up to five days of production before the glass even arrives at the laminated safety glass line. If we have promised the customer a delivery time of two weeks, for example, we have to get it right first time. Not to mention the labour and energy costs that have already been incurred by the product when it arrives for lamination.”

Reflecting back on the project, Baumgartner added, “My advice for anyone looking for a new pre-lamination system would be to: look at the complete package. The complete package that LiSEC offered us is perfectly tuned. We got what we were promised. I was pleasantly surprised by the throughput speed, which in real operation is a little faster than advertised for all thickness distributions. I think many things have been well thought out and cleverly resolved, and we have not yet identified any major weaknesses when it comes to maintenance requirements and accessibility.

“From time to time there has been a need for minor adjustments for special build-ups, but so far we have found a solution for every requirement together with LiSEC Support. If the system continues to run for ten years like it has for the last two months, I will be very happy indeed.”