ISRA VISION presented its new “all-in-one” surface inspection system “FPM-Smart”at glasstec 2024, which enables complete optical defect detection and classification at line speed.

The non-contact conveying of the glass ensures speed. Because the compact system combines a large number of inspection channels and measures light deflection in transmission and reflection, as well as inspecting in light and dark field, it can detect and classify defects more precisely and draw valuable conclusions for the continuous optimization of production.

FPM-Smart is an “all-in-one” inspection system that has been specially developed for the inspection of finished or prefabricated parts such as ultra-thin cover glasses, UTG folding glasses and highly developed transparent films. Glass or film structures consisting of several layers can also be inspected and even viewed separately.

Algorithms also enable the inspection of free-form surfaces and intelligent multi-zone inspection. An ultrasonic sonotrode, which vibrates at 35,000 Hz, generates a standing wave and thus creates an overpressure that causes the glass to float at a controllable height of between 10 and 100 micrometres – 10 micrometres is one hundredth of a millimetre.

The camera structure of the compact system uses a large number of inspection channels: In the TBF (Transmission Bright Field), the inspection beam is set so that the camera looks into the light source – defects appear dark. In the RBF (Reflection Bright Field), the new ISRA VISION system also inspects light deflection for the first time.

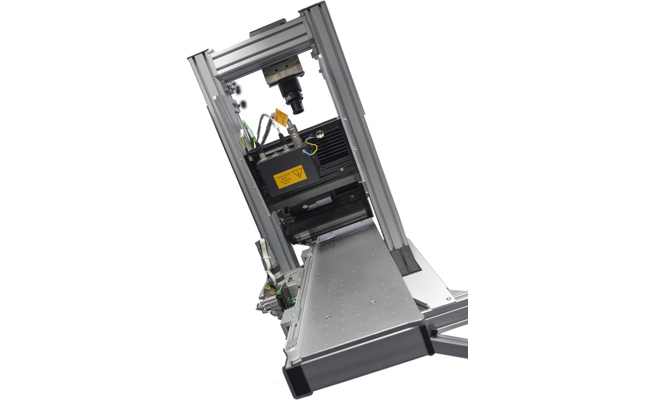

Compact and powerful

FPM-Smart combines the different systems in one compact system measuring just 1,300 mm long x 844 mm wide and 1832 mm high. It reliably detects all defects such as scratches, spot and etching defects, inclusions, bubbles, edge chipping, fingerprints, dirt, dents and dings. The conveying speed is 2.5 to 9 meters per minute, depending on the translucency of the glass to be tested.

Test specimens with a light transmission of 80 percent or higher benefit from the maximum speed; darker variants, which are used as backsheets, for example, require a little more time.

ISRA VISION is already working on a future extension: additional superstructures (FPM-SmartEdge) will allow the edges of the glass to be viewed again at a much higher resolution in order to detect micro-scratches, for example.