“When we buy a new TV or piece of furniture for our home, it gives us good vibes – a nice feeling. In a similar way, we chose to upgrade our tempering furnace to make things easier and better for our team, so their work would be more enjoyable,” said Pedro Aguilar, Managing Director of Vitropor.

More than 30 years ago, Vitropor was founded by Pedro’s father to temper glass in northern Portugal, about 10 kilometres north of Porto. Despite the huge demand for tempered glass, the Portuguese market had little to offer. Mr. Aguilar visited the main glass processing industry exhibitions, Glasstec and Vitrum, to source the best tempering machine for his new company. Tamglass, now Glaston, was one of the best even then.

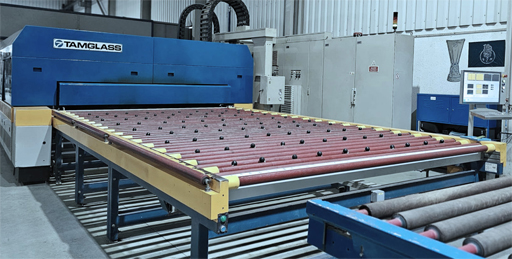

Vitropor grew throughout the years and eventually consolidated its three locations into one new production site. In 2001, the company purchased a Glaston laminating line and a new ProE tempering line to replace its older HTF line.

Today, the 50-person company serves the appliance, automotive and architectural markets. “We see ourselves as a niche company, present in several markets with a diversified portfolio,” Pedro explained. “We seek to deliver solutions that inspire our customers and communities.”

Always finding ways to improve

“Whenever we have the opportunity to improve the quality and efficiency of our business or that of our operators’ work, we don’t hesitate,” Pedro said. “We don’t have the budget to invest in a new production plant or line every 20 years.”

When he was approached by Glaston with proposals for upgrades, he was happy to move forward. One of the upgrades two years ago involved adding an autoclave to the older lamination line.

The most recent upgrades, carried out in two phases, included the iControL system, the Roller Heat Control (RHC) system and new solid state relays to tempering line.

Upgrading step by step

For Vitropor, the best way to upgrade was step by step. In August 2022, the ProE tempering line was first upgraded with the Glaston iControL system to add more functionalities.

In August 2024, Vitropor used its summer holiday break to complete the RHC and solid state relays upgrades. The solid state relays are a new technology that ensures more stable temperature control.