Sirkel Materialgjenvinning AS from Oslo, the only glass recycler of packaging glass in Norway, is situated in Fredrikstad, recently commissioned Binder+Co for the delivery of a recycling plant for glass in Fredrikstad. This installation will be the most modern one of its type and can process 45 tons of collected glass and metal per hour. The glass is sorted as of a size of 5 mm into different coloured products (clear, green and brown glass), and metal is sorted into ferrous and non-ferrous fractions.

The recycling company from Norway has used technology from Binder+Co for more than 25 years. Hence, not only was the existing waste glass recovery plant from the year 1992 designed, built and subsequently expanded several times by Binder+Co, but know-how from Binder+Co is also used in the customer’s plant for foam glass production with the DRYON fluidized bed dryer.

The new plant will provide Sirkel Materialgjenvinning with the greatest possible flexibility in the processing of its products. Depending on the requirement, the customer can recover the entire quantity of recycled glass in the highest quality for sale or use part of the glass cullet for foam glass production. With this concept, Binder+Co ensures the maximum material yield for Sirkel Materialgjenvinning.

This order substantiates the company’s market leadership in the recovery of waste glass and, at almost 14 million euros, it is the biggest order awarded to Binder+Co in the recycling area, as Jörg Rosegger, Member of the Executive Board of Binder+Co AG explains. Through its broad range of machines for processing bulk material, Binder+Co AG is able to supply the complete process to Sirkel Materialgjenvinning, from glass crushing, continuing with screening and cullet sublimation up to sensor-based sorting. In order to optimally prepare the waste cullet for sorting Binder+Co has developed cullet sublimation. The essential process steps are drying, cleaning, polishing and dust removal.

In Norway, glass and metal cans are logistically collected together. Therefore, both recyclable materials are processed in the new plant. Besides pre-treatment with screening, metal separation, comminution and organic separation, the plant includes metals processing by separation of ferrous and non-ferrous metals as well as the so-called cullet sublimation, which is decisive for the efficiency of the subsequent sorting stages of the coarse and fine fractions.

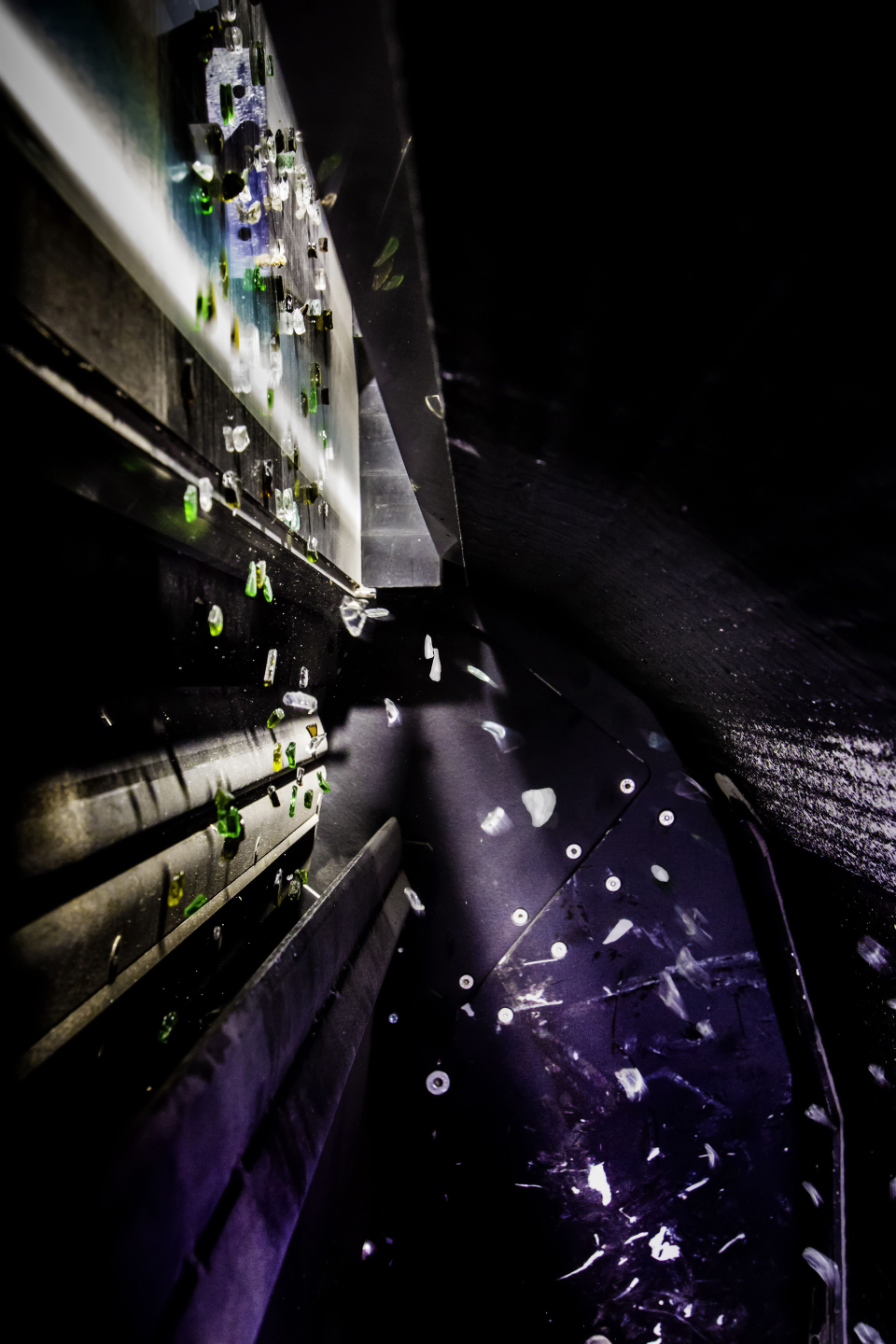

The sorting stages with 16 CLARITY sensor-based systems are the heart of the plant. They produce mono-fractions of flint, green and brown glass cullet. The glass is separated from any interfering glass ceramics and leaded glass with patented UV technology.

In this project, Binder+Co takes over both the machine technology as well as delivery of the complete plant from the structural steelwork up to extensive peripherals such as pipelines, chutes and electrical installations. Acceptance of the waste glass recycling plant is slated for the end of September 2019.