Fully modular and scalable system

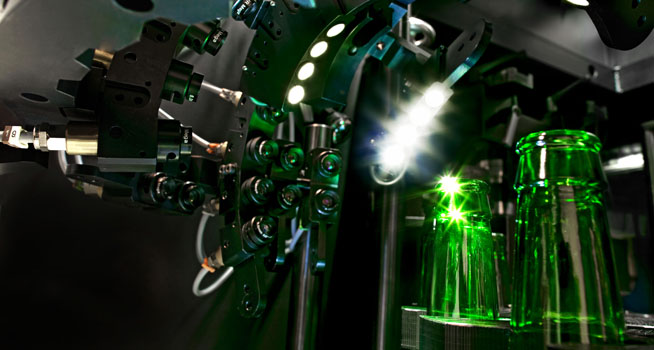

A Ranger 2 system consists of one camera, collecting five images simultaneously via five lenses and fibre optic image guides, the illumination unit and the control unit with the software for image processing, including the decision “container okay or not okay”. Based on the budget and needs of the glass plant, they can start with one system and add any number of parallel systems whenever they want. A typical and recommended configuration would be four parallel systems, each dedicated to and optimized for one of the following types of checks:

- horizontal;

- shoulder;

- vertical;

- bottom.

Each system runs independently and does not need to be synchronised with the others. So there is no influence or need to compromise between the systems. This allows an individual optimisation of all settings (illumination etc.) for the respective type of check. If one system is not available or not adjusted optimally, the others are still fully operational.

Intelligent cloud masking – self-learning systems

Intelligent cloud masking – self-learning systems

Every container produced must be regarded as a unique object and any check detection concept has to respect this. For this reason each Ranger 2 system is using Heye’s Intelligent Cloud Masking (ICM). Bearing in mind that each article is distinctive, the Ranger 2 system is designed to investigate each one independently. Accordingly, it’s not necessary to teach the detection system, but each container serves as a time saving reference for itself.

Moreover, the inspection zones are dynamic in nature. The Ranger 2 system is therefore able to detect different variations of checks, as well as to recognize new variations of them during production.

Smart data – eliminating borders between hot- and cold-end

Apart from advanced camera and non-contact solutions, smart data is the key. The Heye PlantPilot collects and aggregates production data in the plant. The borders between Hot End and Cold End will disappear, information is shared on the spot. Tracking and tracing as well as the possibility of creating user-specific analysis are additional components, allowing continuous improvement processes to increase productivity.

Self-learning systems are one of the cornerstones of Industry 4.0. The Ranger 2 camera check detection proves to be the best solution in the market. Heye’s clear and innovative product strategy, integrating latest camera solutions, remains unchanged.