The Glass Systems Group, which has been owned by Press Glass since September 2015, consists of a total of six sites in the UK and produces approx. 80,000 to 100,000 insulating glass units per week.

A company in constant growth

Glass Systems Ltd. was founded in the 1980s by Claire Wood and John Wood. The company started by supplying sealed units to customers in South Wales. In the following years the company has grown. It focuses on high quality products. More and more satisfied customers outside Wales, along the M4 corridor, allowed Glass Systems to grow successfully, so that investments were made in production and Glass Systems began to temper glass itself. Further expansions and acquisitions followed.

Today the Glass Systems Group comprises three separate companies with a total of 1,000 employees. The company’s portfolio offers customers the full range of products and services for the window, door and conservatory industry. Glass Systems mainly supplies insulating glass – the size of the customers varies – so Glass Systems has customers who buy 50 insulating glass units per week, but also customers who buy 5,000 insulating glass units per week.

Today the Glass Systems Group comprises three separate companies with a total of 1,000 employees. The company’s portfolio offers customers the full range of products and services for the window, door and conservatory industry. Glass Systems mainly supplies insulating glass – the size of the customers varies – so Glass Systems has customers who buy 50 insulating glass units per week, but also customers who buy 5,000 insulating glass units per week.

On the road throughout England with their own fleet of vehicles

On the road throughout England with their own fleet of vehicles

The company is characterised by the fact that they can deliver throughout the United Kingdom. From Aberdeen in Scotland to Cornwall in the south of England. This is made possible by their own fleet of around 60-70 vehicles.

“There’s no place in the U.K. we can’t deliver to,” said production manager Khaled Elleboudy. To make deliveries as efficient as possible, Glass Systems uses automated route planning. “We have about 700 customers, so automated route planning is essential. We’re trying to achieve even greater traceability.” This is not the only area where the company focuses on profitable software.

In cooperation with LiSEC, Glass Systems is constantly developing the LiSEC software further, in order to work optimally and efficiently.

Glass Systems relies on LiSEC – for software too

The cooperation between Glass Systems and LiSEC started when the (then) new production facility in Swansea was opened and investments were made in LiSEC software products such as LiSEC GPS.order and LiSEC GPS.prod.

After the implementation of LiSEC GPS.order – the LiSEC software for order management, which accelerates and automates the processing of quotations and orders – and LiSEC GPS.prod – the LiSEC software for optimal production planning, which covers the areas of production planning, scheduling, glass cutting optimization, sequencing and re-cutting management, more and more investments have been made in the product portfolio of the all-round partner LiSEC over the years.

After the implementation of LiSEC GPS.order – the LiSEC software for order management, which accelerates and automates the processing of quotations and orders – and LiSEC GPS.prod – the LiSEC software for optimal production planning, which covers the areas of production planning, scheduling, glass cutting optimization, sequencing and re-cutting management, more and more investments have been made in the product portfolio of the all-round partner LiSEC over the years.

Last year alone, the Glass Systems Group purchased two lines for cutting laminated glass, two LiSEC GFB cutting tables and two LiSEC KSRs. The LiSEC KSR is a glass edge grinding machine for rectangles and shapes, with which all four sides can be seamed fully automatically. In combination with the LiSEC KSV the cycle time can be reduced by approximayely 35 percent. They have also purchased a LiSEC software package for Scotland. Khaled Elleboudy added about the cooperation, “What I appreciate most is the technology and software of LiSEC. We have a really very good cooperation.”

Last year alone, the Glass Systems Group purchased two lines for cutting laminated glass, two LiSEC GFB cutting tables and two LiSEC KSRs. The LiSEC KSR is a glass edge grinding machine for rectangles and shapes, with which all four sides can be seamed fully automatically. In combination with the LiSEC KSV the cycle time can be reduced by approximayely 35 percent. They have also purchased a LiSEC software package for Scotland. Khaled Elleboudy added about the cooperation, “What I appreciate most is the technology and software of LiSEC. We have a really very good cooperation.”

Ged Smith, Managing Director of LiSEC Software UK Limited, about the cooperation said, “We at LiSEC have watched Glass Systems grow rapidly over the years and we are very proud to be a major part in that success, both as a trusted supplier of machinery, and also as a provider of business critical software for their ERP and Production management. We have a great relationship with them and we are working on even more detailed, exciting and innovative projects for the future!”

Ged Smith, Managing Director of LiSEC Software UK Limited, about the cooperation said, “We at LiSEC have watched Glass Systems grow rapidly over the years and we are very proud to be a major part in that success, both as a trusted supplier of machinery, and also as a provider of business critical software for their ERP and Production management. We have a great relationship with them and we are working on even more detailed, exciting and innovative projects for the future!”

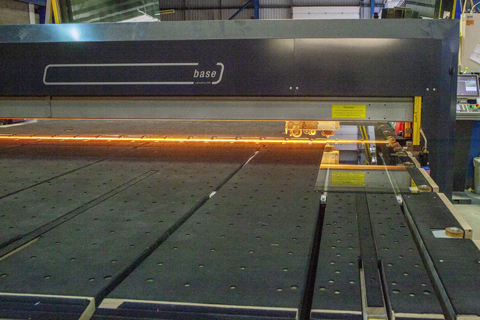

LiSEC base LAMICUT

LiSEC base LAMICUT

In 2018 Glass Systems purchased the LiSEC base LAMICUT, laminated glass cutting machine, at the glasstec trade fair in Düsseldorf.

“We had more orders for laminated glass than we expected, so we had to invest quickly. We bought a cutting table from LiSEC that we had never seen before and that no one in Europe had ever had or heard of before. In February 2019 the cutting table was installed within 10 days and the performance is absolutely outstanding. We cut almost twice as much as before! I would say the LiSEC laminated glass cutting machine is the best machine we bought in 2018,” said Khaled Elleboudy.

He emphasizes that the machine is very easy to operate and offers an excellent price-performance ratio. The machine is also very compact, which makes it ideal for smaller halls. Highlights of the LiSEC base LAMICUT are the Free Fall loading, the extendable lifting arms and the tiltability of the air cushion table. The table offers float glass cutting including a Low-E edge deletion module. Furthermore, the cutting of special shapes is possible.

Glass Systems in the future

Khaled Elleboudy said of Glass Systems’ plans, “In 2019 we focused on growth and investment and were able to increase sales volume by approximately 15-20 percent. This year we want to focus on service and quality. We also want to focus even more on software.”