‘Beyond’ is a concept that characterises Neptun as a company, in its products, in its approach to glass processing and continuous evolution towards ever-increasing quality by maintaining cost- effective solutions.

|  |

Founded in the difficult economic context of the year 2008, in an already saturated market, Neptun finds its strength in the ability to identify and implement innovations that push machinery beyond traditional limits, to perform new functions as well as old ones, in a more effective manner.

INNOVATIVE PRODUCT LINES

Neptun is a unique reality among the manufacturers of flat glass machines. In less than 12 years it has created three completely innovative product lines covered by numerous patents, which contribute equally to turnover.

The company’s straight-line edging machines, washing machines and vertical NCs for drilling and milling have a full range of width and depth and, although very different from each other, they can be fully integrated thanks to the Bravo anthropomorphic manipulators.

This work has involved an enormous technological and financial effort, considering that competing companies with the same turnover range, which have been operating for decades, are concentrated on a single product line and have a secondary one at the most.

ORGANISATION AS A KEY STRENGTH

An important key to Neptun’s success is organisation, both internal and external. Since its launch, in fact, the company has been structured in an industrial manner. From the development of a project to manuals, order entry to warehouse and production management, accounting to after-sale service – all processes are carried out according to clear protocols, guaranteeing the maximum reliability of services and machinery for customers.

Neptun has also made important investments in the creation of a sales and service network, in a scenario where competition has been organised for a long time.

PRODUCTS

Horizontal and vertical washing machines

The company is mainly known for its horizontal and vertical washing machines, sold in over 80 countries and consolidated as par excellence machines for industrial contexts, where nothing can be left to chance.

Straight-line edging and mitring

Neptun is the reference point for straight-line edging or mitring, with virtually one machine installed per week since 2012: tens of millions of kilometres processed with the most robust conveyor that can be found on the market.

Quickline – Vertical NC processing

In the field of vertical NC processing, on the other hand, the concept of Quickline has been widely known, for having brought milling and drilling to a level of speed and accuracy at least equal to the horizontal NCs, but with unprecedented flexibility and costs accessible to all.

The new vertical NC Quick2-T8

Due to a strong outlook to respond to market needs and focus on R&D, Neptun launches new products or updates of existing ones each and every year.

Even in this difficult 2020, they did not hold back and are proud to introduce the new vertical NC Quick2-T8.

Quick2 combines the drilling and milling phases in a single structure, without sacrificing the main benefits of the Quick series. The extreme precision achieved through double positioning control (drilling with a tolerance of +/- 0.15mm), impeccable working quality of the milling process with glass in a fixed position, fast automatic tool exchange (less than 8 seconds), ease of programming and mechanical simplicity are all standard proven features.

Thanks to the Quick2 module, these benefits are now within the reach of those who, due to lack of space, cannot opt for a solution with two separate drilling and milling units. On the one hand, this allows the processing of two glass sheets simultaneously, thus essentially providing double-production; but on the other hand, it has a footprint of only several meters more.

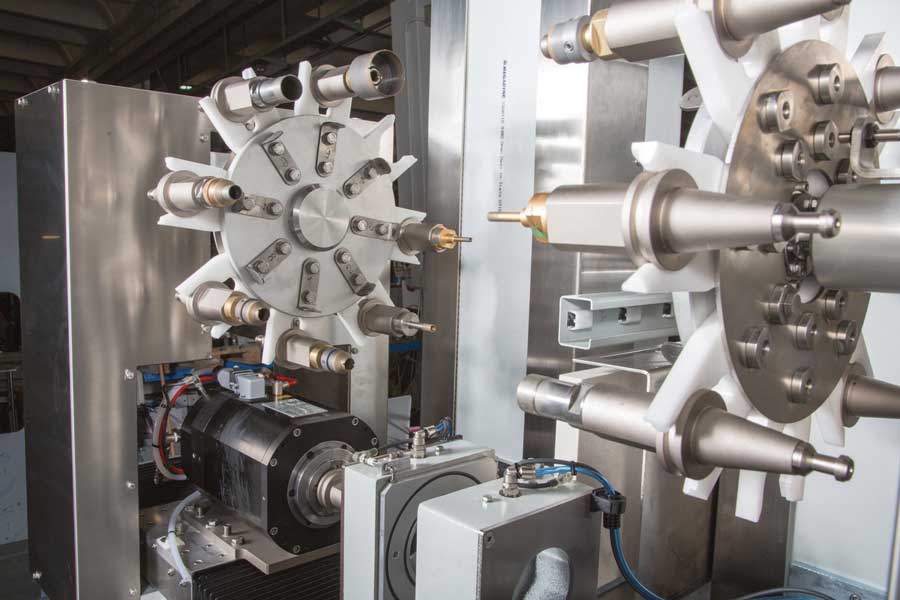

The Awa system

The Rock edger also comes with a new look: the Awa system for the fully automatic management of diamond and polishing wheels, which combines simplicity, precision and consistent reliability over time. With automatic presetting of the diamond wheels, recipes for managing different combinations of removal according to the processing type or set of wheels used, and an automatic compensation system for the polishing wheels, the operator obtains fast and safe machine set-up.

NEPTUN HUB NEW OPENING

To offer customers the opportunity to try our products directly, Neptun have created a real booth of 170 square meters at their premises in Rovello Porro, near Como, northern Italy, where they have the best of their technology on show, including Quick2-T8 and Quickmill, washing machines and the Rock 11 straight line edger with the unique patented AWA system.

In a safe COVID-free environment, customers can come and check machines themselves. The display can also be seen in a video online. This means that everyone has the chance to experience Quick2-T8 NC or any other machine physically or virtually until the end of December.

This goes to show what the company means when they say they go ‘beyond’.

Neptun Srl

www.neptunglass.com