The challenging project commissioned during 2020 by the Russian company Glacem to Revimac–Fusiontec is dealing with the extension of an existing working-end and the supply of a new high performance 100 TpD forehearth.

The dismantling and demolition of the existing parts for the connection and installation of the new working-end extension will be done without stopping the glass production and for this reason a very good coordination between the customer and Revimac has been the key point of the project. All the technical details and engineering documents have been exchanged and agreed upon all along the development of the entire job.

The supply includes the following:

- the complete engineering and design package for the local fabrication of the almost 18 meter long steel structure to support the working-end extension and the forehearth, as well as of the casing to contain the refractories;

- the entire steel bracing superstructure steelwork;

- the complete set of refractory materials (glass contact, superstructure, top and bottom insulation) starting from the junction point at the working-end, to the front block connected to the feeder spout;

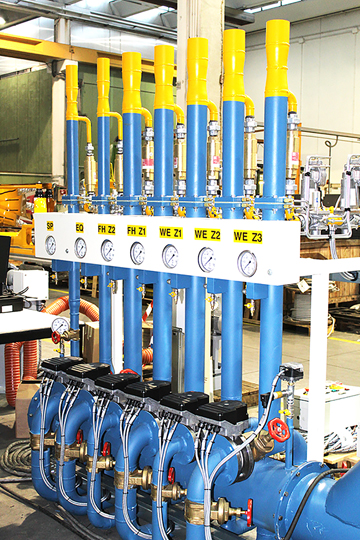

- the gas pressure reduction and feeding unit;

- the combustion and cooling equipment

- the gas burners and burner manifolds;

- the Revimac own control and supervision system.