LandGlass‘ TIGER™ Smart Factory employs the new generation enterprise resource planning system, intelligent manufacturing technology and identification technology to interconnect all machinery throughout the entire process from float glass to finished products. It has realized digital and intelligent processing of supply, manufacturing, and sales information during production, achieving lean and efficient manufacturing and management.

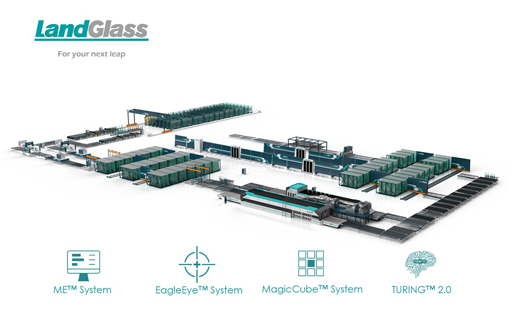

Composition of TIGER™ Smart Factory system

Composition of TIGER™ Smart Factory system

- ME™ System:Integration of EPR, MES system and lean management system, centralized management of production resources;

- EagleEye™ System:Permanent product traceability, allowing for rapid and timely replacement;

- MagicCube™ System:Intelligent classification and delivery, full control of the production rhythm;

- The TURING algorithm, like a built-in glass tempering expert, can automatically optimize and adjust the tempering processing parameters, monitor the tempering production process, record and save the process data and production data 24/7.