Isra Vision’s TOUCH & INSPECT fundamentally simplifies surface inspection in glass production lines.

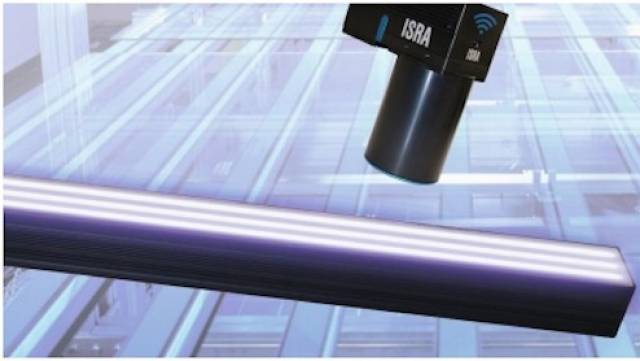

What makes this system truly remarkable is the wireless communication between its core components, enabling a simplified flow of information and quick adaptation to new tasks – for maximum flexibility and optimum decision making processes. The TOUCH & INSPECT concept makes use of the latest IT technologies and combines them with tried-and-tested inspection technologies. The result is a highly-flexible, modular and smart system architecture that provides an ideal basis for decision-making processes during production. After a quick and easy installation process, production can begin immediately. The system’s three core components – lighting, camera and mobile terminal – are connected wirelessly via WiFi. Together, they form an innovative and highly adaptable system architecture for a great variety of inspection tasks and unlock great customer benefits with a cost-efficient design. The mobile terminal – a tablet, for example – operates the system throughout the plant and displays the measurement results captured by the smart camera. Thanks to the terminal’s wireless connection, users can move around freely and flexibly. Compatible with multiple systems, the terminal offers easy access to various inspection systems and can be used to display user and application-specific process, quality and maintenance data. The smart monochrome or color camera with high computing performance directly processes the data captured. Thanks to the innovative camera technology and high computing power, large inspection surfaces can be captured in high resolution – using just a single camera. The smart LED lighting can be controlled remotely. Boasting a state-of-the-art and cost-efficient design with outstanding value for money, TOUCH & INSPECT enables new markets to be tapped and activities in existing markets to be improved. Wireless connection for a rapid flow of information Thanks to their user-friendly connection capabilities, the inspection systems can be connected to each other and exchange information. As a result, multiple sets of inspection data from various process steps can be aggregated. Glass manufacturers benefit from a consistent and reliable stream of process data. Sophisticated software supports process monitoring and data analysis processes with a varying degree of detail – from shop floor management to strategic planning. In addition to automated and objective quality control, the adaptive inspection technology thus enables considerable increases in process efficiency. The data obtained can be used to optimize processes in a targeted manner and serves as a basis for making well-informed decisions on production. TOUCH & INSPECT is the key to advanced production processes and Industry 4.0 in glass production.