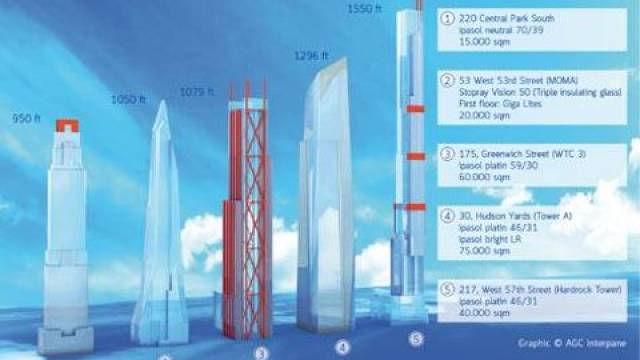

17 skyscrapers going up in New York are being fitted with solar protection glass supplied by AGC Interpane.

The projects involved have attracted international attention and include the World Trade Center, Hudson Yards, the Museum of Modern Art, and Hard Rock tower, to name but a few. In March 2016, 29 projects were under way throughout the USA, and this figure looks set to rise. The architects include Kohn Pedersen Fox, Adrian Smith + Gordon Gill Architecture, Richard Meier & Partners Architects, Rogers Stirk Harbour + Partners, Foster & Partners, and other eminent architectural firms. So the company’s international business is booming.

The main driving forces behind this growth are Interpane’s German plants in Plattling (Bavaria) and Lauenförde (Lower Saxony), whose highly qualified sales staff and promoters are pushing hard to develop international business. And their efforts are certainly paying off: in addition to ultra-selective solar control glass such as ipasol neutral 70/39 and Stopray, the highly reflective coatings (like ipasol bright, ipasol platin) are in high demand in the USA.

The international trend “big is beautiful” also holds true for America, so global demand for glazing products in maximum formats is rising. These oversized units are used whenever architects want to clad entire facades with as few glass sheets as possible to produce exclusive big-impact architecture. This is one of the company’s key strengths, because with products like Giga Lites, AGC Interpane is developing high-end units that are reputedly among largest coated glass products in the world. The maximum deliverable size in float glass is 18.00 x 3.21 m and the maximum sheet thickness is 20 mm