The Dimensional Sampling Gauge (DSG) from Agr is configured for the unique handling and measurement requirements of small format ware such as pharmaceutical vials, cosmetic containers and related products.

The latest version of the Agr’s Dimensional Sampling Gauge (DSG), the DSG-P is targeted towards manufacturers of small ware. The DSG-P is configured for the unique handling and measurement requirements of small format ware such as pharmaceutical vials, cosmetic containers and related products. Retaining the same capabilities of the standard DSG, this version specifically addresses the high precision measurement needs of manufacturers of this type of ware including very small finish attributes as well as body and ID measurements.

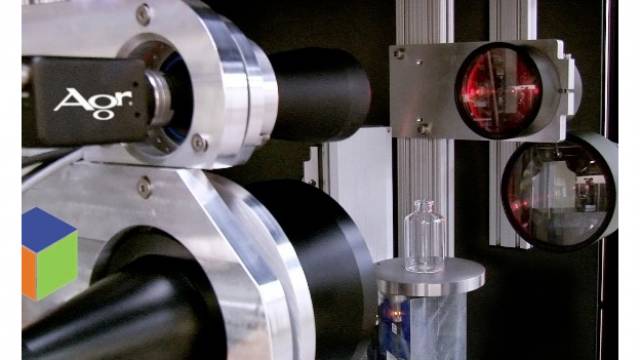

Like the standard Dimensional Sampling Gauge, the DSG-P provides accurate, repeatable and comprehensive measurement of critical dimensions, with a special focus on measurements of ware down to 38mm in height and diameters under 70mm. This automated, self-contained testing station can process a complete set-out of bottles and work unattended to perform a number of critical dimensional measurements, in a single hands-free operation.

The system design offers a modular approach that includes a robotic handling system as well as measurement stations for body/finish dimensioning, weight and ID/Bore/Pushup. An optional station incorporating Agr’s Thickness 360™ wall thickness measurement system is also available. Data from each station is correlated by the system to mould number and available in one consolidated report via the user interface.

Measurement features:

Weight measurement – The DSG-P provides the capability of monitoring individual bottle weights to a high level of accuracy of + 1g.

Finish and Body measurements – The Finish and body dimensional measurement station is the central function of the DSG-P and offers unlimited measurement capabilities. The DSG-P incorporates multiple, high-resolution, telecentric cameras to perform measurements over the entire container body and finish. Bottles are placed in the finish and body station by the robot then positioned in front of the cameras by a high precision table with 360 deg. rotational capabilities. A complete circumferential scan is performed on each bottle, providing a comprehensive image for measurement processing, making it possible to process simple as well as very complex measurements at multiple locations to a very high degree of accuracy and repeatability. All measurements are completed within 30 seconds regardless of the number and complexity of measurements specified for the job.

ID/Bore and Pushup measurements – For ID/bore measurement, the DSG-P features a special small-bore gauging system that can measure bores as small as 11mm. Functions can be programmed for multiple level measurements or a continuous scan to a depth of 40mm. A graphical representation of the finish profile is provided for quick evaluation and visualization. Push-up measurement is also performed in this station.

Thickness Measurement – As an option, the DSG-P can be fitted with Agr’s Thickness 360 measurement gauge. This high-precision device, accurate to + 0.02mm, utilizes the visual scan data gathered by the DSG-P imaging system to position the thickness sensor for optimal measurement. With this approach, the bottle orientation and shape is fully understood making it possible to achieve optimal accuracy, even on curves, corners and difficult-to-measure regions.

Throughput of up to one hundred bottles per hour is facilitated via a pipeline approach where measurements are performed simultaneously in all stations. The robotic handling system precisely moves containers through each station, providing smooth bottle transition, automatic centring and positioning for precise measurement.

The user interface on the DSG-P incorporates touch screen technology for ease of operation. Measurement information is displayed on a high-resolution, colour monitor in a number of formats that enable an operator to monitor critical areas of a container and quickly assess testing in progress. Typical bottle measurement routines are pre-programmed and customized tests can be easily created, providing great versatility in job creation and setup.

The DSG-P is available in several configurations including:

Stand-alone measurement station for automated laboratory applications in the laboratory, or along the production line

Or, as part of Agr’s OmniLab automated sampling station, it can be connected to the line via a sampling conveyor, and configured to work with other online devices to receive select containers at regular intervals for automated dimensional measurement.

The DSG-P, Thickness 360™ gauge and OmniLab® are part of Agr’s broad line of laboratory testing and quality control devices for the glass container and filling industry.