After 15 successful EME NEND® batch charger installations at the Wiegand-Glas locations in Germany – Steinbach am Wald, Ernstthal, Großbreitenbach, Schleusingen – Ernstthal plant once again trusts in the performance and reliability of an EME-NEND® charger.

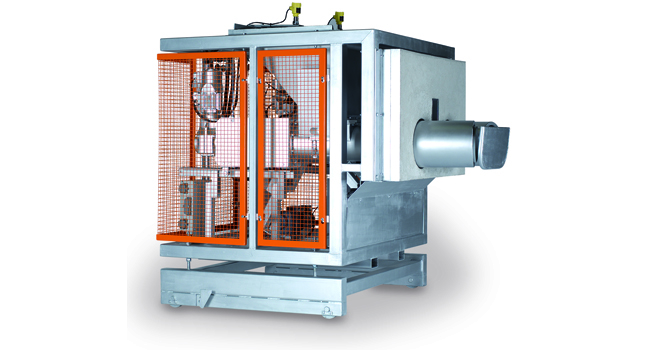

For many years, Wiegand-Glas has been using the whole range of different versions of the EME-NEND® charger (and the EME-NEND®-S charger) with transport screws. Likewise, the latest generation of the EME-NEND® family – the EME-NEND®-R with vibratory feeder – has been successfully in operation for more than one year at the location in Großbreitenbach.

For many years, Wiegand-Glas has been using the whole range of different versions of the EME-NEND® charger (and the EME-NEND®-S charger) with transport screws. Likewise, the latest generation of the EME-NEND® family – the EME-NEND®-R with vibratory feeder – has been successfully in operation for more than one year at the location in Großbreitenbach.

EME is pleased and proud that the EME-NEND® charging technology has proven itself so successfully at the renowned container glass manufacturer Wiegand-Glas for many years.

Along with the many advantages of the EME-NEND® series; there is also no uncontrolled entry of false air into the furnace, a reduction of NOx emissions, a reduction of energy consumption, less heat losses as well as less dust formation based on the sealed doghouse, the EME-NEND® series offers great benefits.

Due to the individual adjustment possibilities of the screws and the pusher, both the batch charging pattern and the batch distribution in the furnace are perfectly matched and optimized for the melting process. Maintainability and reliability characterize the whole EME-NEND® family.