Two 20-year-old glaziers, a van, 120 square meters but much enthusiasm and passion: these are the ingredients with which Artigianvetro was established, today a well-known reality in the Italian glass sector, thanks to a quality production that includes structural, residential, commercial and interior glass panes.

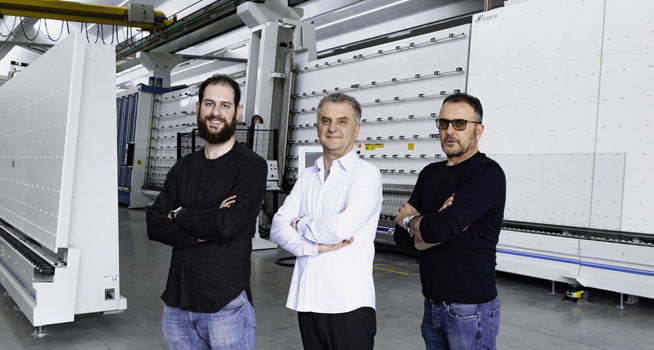

Artigianvetro has had several site changes since the first site, up to the current production plant. The latter is a real gem: a surface area of 4,000 square meters, completely independent from an energy point of view thanks to a system of last generation photovoltaic panels. Today, Artigianvetro employs approximately twenty people, coordinated by the Marcantonelli family: in fact, the founder Graziano and his brother Daniele were joined over time by his wife Patrizia, and their sons Nicola and Noemi.

“Artigianvetro has grown one step at a time, with passion and dedication” said Graziano Marcantonelli. “The collaboration with Forel began in 1997, when we purchased the first flat plate coupling press. The quality demonstrated by the product, combined with the trust that was established with the supplier, took us a little at a time to choose Forel also for the following investments.

Today we use a edging line and an arrissing one, which feed our IG unit production line (all Forel): the last one allows the assembly of units with both rigid and flexible spacers, depending on the orders. However, we wanted to take a step forward through integrated logistics, a fundamental component for any modern glassworks. So, a year ago, we revolutionized our daily business with the purchase of the Forel Sorting System. After considering other options available in the market, we choose the SS for performance and efficiency: we automated the management of glass sheets, simplifying the work of the operator and increasing productivity and safety”.