The insulated glass manufacturer Wolff + Meier is blazing new trails with the digitalization of templates.

Dennis Weitmann, Production Manager at Wolff + Meier, is piloting A+W iShape with his team and using it in real-time operation: “The biggest advantage of A+W iShape is that we have a mobile solution that we can use to digitalize templates quickly and easily without occupying cutting tables.

“It’s easy. All I have to do is take a picture of the template, there’s no need to do much referencing in advance. Digitalizing the shape is much faster than before because I can take care of it with a single photo.”

Dennis Weitmann photographs the template in front of a reference object, which the program uses to correct any distortions.

A+W’s software recognizes the contour and transforms it into a stream of points. This point stream is transformed into a shape defined by arcs and lines and the shape is then used for further processing.

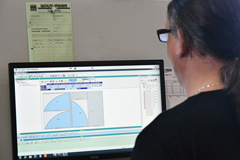

Next, the shape is displayed in A+W’s CAD Designer software, where it is further refined. Here, incorrectly recognized contours, such as labels, traces of labels, or other fasteners, are corrected. In the end, you have a clean, exact CAD file for the template. The CNC files for production are generated directly in A+W CAD Designer. Half an hour after the ‘click’ of the smartphone camera, you can produce the lite, precisely to the millimeter according to customer specifications.

The experiences of the Wolff + Meier production team are extremely valuable for the A+W developer team. As is the case for any software being piloted, there is always room for improvement. Thank you to Wolff + Meier for supplying practical ideas to A+W’s development.