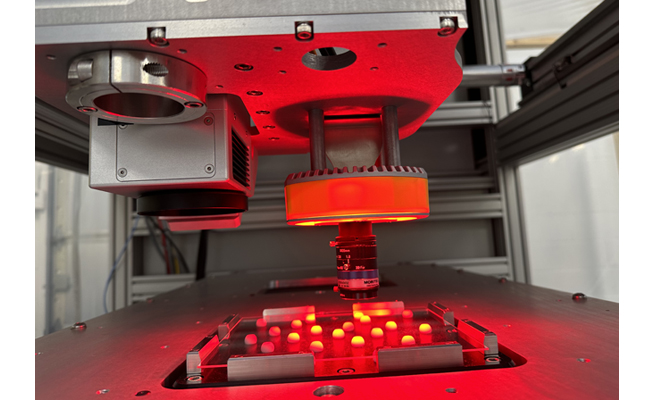

Bold Laser Automation, Inc., a leading provider of cutting-edge automation solutions, has announced the launch of the LPB4040C Laser Precision Bessel Structuring System, a cutting-edge solution that promises to transform the way thin glass substrate processing is performed. This ground breaking system harnesses the power of the ICE Fire Picosecond IR laser in conjunction with the Coherent 30-Watt Diamond series laser to deliver unmatched precision and efficiency in glass release processes.

The LPB4040C system is designed to set a new standard in the glass fabrication and cutting industry thanks to its innovative features and capabilities. This system is equipped with a precision overhead linear motor gantry, offering micro-level accuracy that ensures the most intricate structuring and processing tasks can be completed with absolute perfection. Furthermore, the dual inline conveyor platform provides a remarkable increase in throughput for palletized processing applications, making it an ideal choice for high-volume production environments.

For those seeking high accuracy in low-volume applications, the LPB Series can be configured with a standard manual loading XYZ Motion System. This versatility allows businesses to tailor their processing set-up to their specific needs, whether they require the speed and throughput of an automated system or the precision of a manual configuration.

One of the stand-out features of the LPB4040C system is its integrated machine-machine technology, which offers a hands-off platform for a wide range of industrial applications. This advancement in automation technology not only improves efficiency but also reduces the potential for human error, enhancing overall process reliability.