Innovation and Customisation, Flexibility and Reliability, Performance, Quality and Working speed are the characteristics of each Bovone product. In over 65 years of production at the highest levels, Bovone Elettromeccanica has established itself as an international reference leader for the supply of stand-alone machines and full-line systems, accessories and tools for the second processing of glass and natural and synthetic stone.

|  |

Bovone Elettromeccanica’s leading position in the flat glass machinery sector comes from the continuous analysis of the multifaceted and frenetic trends of these reference markets, constantly studying new solutions capable of equipping its customers with cutting-edge technologies in view of present and future challenges. Solutions with a very high technological content for applications aimed mainly at the construction,

furniture and automotive sectors.

Production takes place entirely in the company’s premises in Ovada, Alessandria, northern Italy, which is a par-excellence infrastructure both in the Italian and international industrial scene, able to manage every step in-house, from the supply of the best raw materials to the development and integration of management software, up to the proposal of the most suitable tools, thanks to synergy with sister company BDT, Bovone Diamond Tools.

In addition to the Ovada headquarters, Bovone is also present on the market with two direct branches, one in the United States dedicated to the North American market, and the other in Brazil to cover South America. In addition, a widespread network of distributors present all over the world guarantees the presence of Bovone at global level.

An articulated and highly qualified system of technicians, supported by the almost unlimited availability of stock, provides excellent after-sales service, responding promptly and competently in every geographical area.

Bovone machines and plants combine high quality with processing speed, and continuous innovation with the drastic reduction of machine downtime thanks to their extremely high reliability.

THREE REFERENCE PRODUCTION AREAS

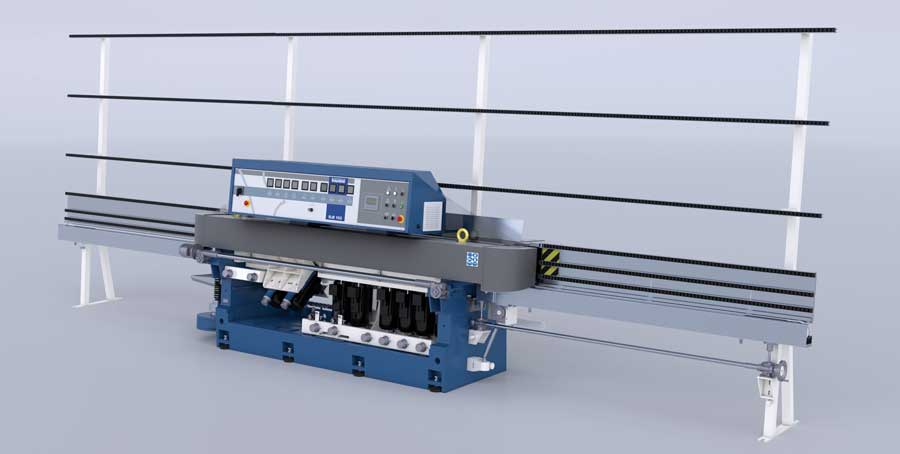

Machinery

Stand-alone machines for the treatment of glass sheets: grinding, bevelling and washing machines for glass. The main aspect of this area is the high degree of customisation which, today, is a fundamental strategic plus: Bovone machines, in fact, are designed to solve each and every production need. They ensure perfect finishes for increasing production yields thanks to their high speed, combining the most advanced electronic applications with the sturdiness of construction and reliability guaranteed over time. Entry level or more advanced machines from Bovone are able to guarantee excellent performance.

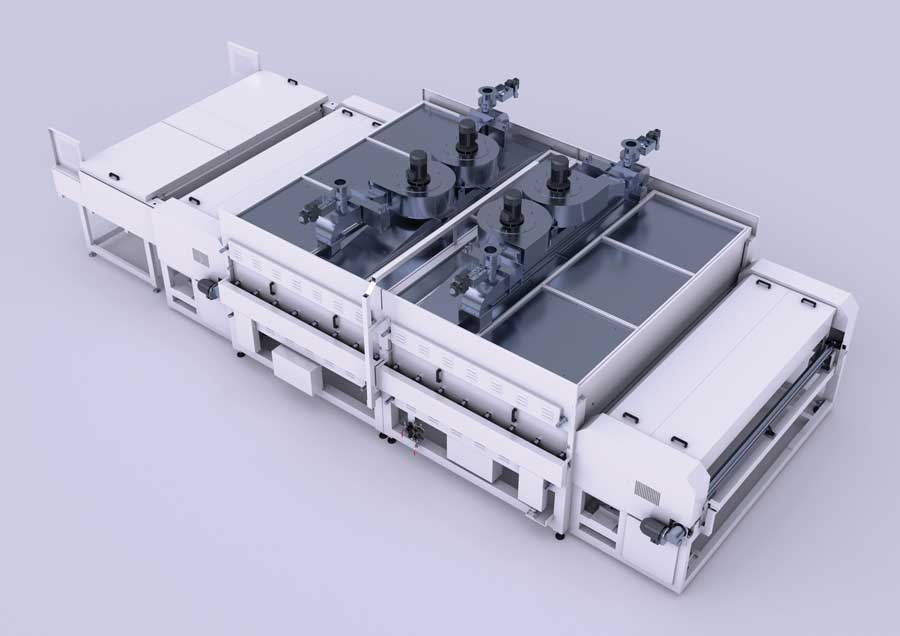

Systems

Silvering lines and laminating glass systems can be completely customised and integrated according to the specific needs of each customer. All construction details are customised and calibrated, compared to standard configuration, to meet specific needs. Bovone plants ensure the highest performance both for large-scale productions and for those where high flexibility is required.

BRS – Bovone Robotic Systems

Production also includes the BRS area, fully automated robotic Bovone systems for glass grinding. BRS systems integrate straight-line edging machines and articulated, multi-axis robots, with different load and application characteristics. With regards to applied industrial robotics, Bovone is Kuka’s Official System Partner. BRS adheres perfectly to Industry 4.0 protocols: the islands work without the presence of personnel and are fully connectable for traceability and self-regulation of production parameters.

NEW PRODUCTS AND SERVICES

HCR Furnace – Hybrid Convection Radiation

HCR hybrid laminating furnace, a combined technology to achieve maximum production versatility. The lamination market is closely linked to the construction, architecture, automotive and transport sectors, where laminated glass, by virtue of its qualities in terms of safety and comfort, is widely used, and where new materials with excellent performance are constantly sought. Bovone’s new hybrid furnace was created to respond to these markets.

With this new Made in Bovone technology, the hot air convection system no longer needs IR lamps: the air is heated by a resistance system inside the furnace. The new furnace manages the materials by integrating the two heating systems – radiation and convection – completely independent from each other. These can be combined according to the needs imposed by the type of glass sheet being processed.

In addition to its high versatility, the furnace also guarantees heat distribution optimisation, monitored by a sophisticated control system, providing greater uniformity of the glass temperature with tolerances of ± 2°C. The control panel is very simple and intuitive, with easy access to a wide variety of settings, including the management of the individual IR lamps, immediately guaranteeing excellent results in the combination of the two systems – even for inexperienced operators.

Furthermore, thanks to accurate mechanical design, maintenance operations are extremely easy, while excellent construction quality guarantees reduced consumption, with energy savings of over 40 per cent compared to other technologies on the market.

In terms of service, and in line with its role as a market leader for technological innovation, Bovone has developed a number of Industry 4.0 solutions to increase its automation and remote working services.

BVA – BOVONE VIRTUAL ASSISTANT

Bovone Virtual Assistant is a system to provide remote access to all data, manuals, certificates and technical videos relating the machine, using a simple IPad device that is supplied with the machine.

This product becomes an ambassador of cutting-edge technology and the degree of innovation that Bovone is able to introduce in its reference sector. BVA is part of the panorama of solutions designed to facilitate both automation levels and remote interventions as much as possible.

In this particular moment of distancing, remote assistance acquires even more meaning and value. In fact, in the glass processing sector, where production set-ups must be constantly calibrated and reviewed, Bovone is at the forefront in countering the critical issues generated by distance. This is combined with the skills of a highly qualified service team ready to be in direct contact with the machines installed around the world to diagnose, solve and optimise.

This technology allows to save considerably in terms of time, human and economic resources. Speed of intervention and efficiency are guaranteed.

INDUSTRY KIT FOR REMOTE ASSISTANCE

The Bovone product range is equipped with the Industry Kit For Remote Assistance, which allows to be connected online via an Ethernet cable. The remote connection guarantees that wherever the machine is located in the world, an internet connection will be sufficient to allow Bovone technicians to intervene directly, solving most of the support requests remotely.

Thanks to remote connection, technicians can intervene immediately to assist and support customers in the case of incorrect settings or inadequate recipe parameterisation operations, or any other unsuitable operation that leads to the generation of an alarm, guaranteeing immediate problem solving and a drastic reduction of line downtime, thus protecting productivity. Production data collection for predictive maintenance and use and performance of the same is another interesting aspect of this service.

A further effort made by the company to assist its customers in after sales.

Bovone Elettromeccanica Srl

www.bovone.com