The strategy of companies operating in the flat glass processing sector is currently that of searching for ever greater production flexibility and, consequently, the proposals of equipment manufacturers must be able to meet the needs of an increasingly changing and heterogeneous market.

|  |

Bovone’s decision to design a new machine capable of creating a totally different and new profile of the glass slab compared to those that can be obtained with its other vertical edgers came from the continuously increasing demand for production flexibility. The new machine – the Bovone ELB 9 + 2 – has thus become part of a range of products capable of carrying out a series of quality workmanship, which is increasingly vast and sought after.

The search for quality and flexibility in processing cannot, however, be separated from the need to maintain high levels of productivity.

RESPONDING TO NEEDS WITH TECHNOLOGY

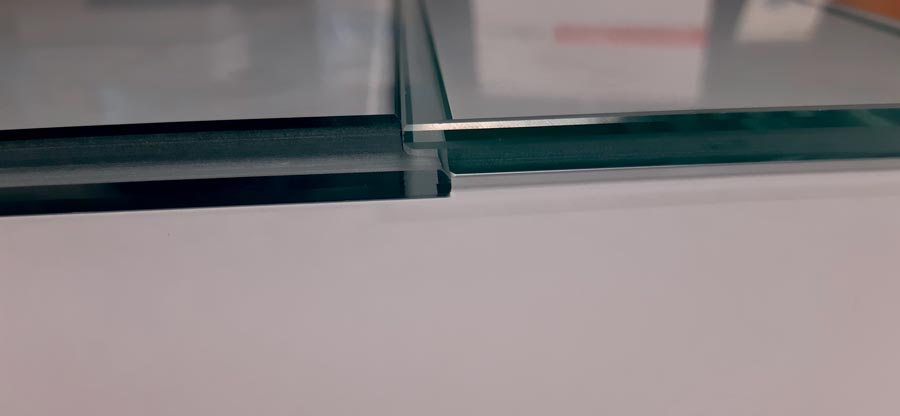

The new straight-line edger ELB 9 + 2 by Bovone responds to the needs of the reference markets – architecture, interior design, home appliance – combined with the technological push that the company puts in all its products, together with its subsidiary Bovone Diamond Tools. The in-depth study of tools has led the company to use and configure the grinding wheels in such a way as to allow to create a stair groove and arris in a single step.

The depth and height of the groove can be adjusted by operating in a range of 0.02 mm: a very fine and precise adjustment up to a maximum of 5 mm on both axes. The two arrises are adjustable and can be excluded when a sharp corner must be created, functional to the subsequent coupling between glass or between glass and other materials.

ELB 9 + 2 is able to process glass sheets or other materials – ceramics, artificial stone and natural stone – with a variable thickness from 2 to 30 mm.

The body of the machine is the same as the famous ELB12: sturdy cast iron base and cutting-edge construction solutions are integrated with high-end electronics.

FURTHER IMPROVEMENTS

External remote control

A further improvement has been introduced to facilitate the user’s operation: the machine is equipped with an external remote control for the movement on the X and Y axes of the two spindles relating to the grinding wheels dedicated to grinding the groove and for the height compensation of those relating to the polishing wheels of the front and rear arris and of the flat edge. In particular, the automatic adjustment of the polishing wheels, being more subject to wear, is functional to safeguarding the life cycle of the wheels themselves, obviously maintaining the quality and production standards of polishing unaltered.

Robotic systems

Just like the other straight-line edgers of Bovone’s ELB line, ELB 9 + 2 can be integrated with articulated, multi-axis robots, inside the BRS Bovone Robotic Systems – robotic islands for grinding: the perfect solution to optimize production since the handling of the glass sheets takes place quickly, safely and with high precision.

Complex profiles in a single pass

The innovation lies in being able to create a complex profile on the edge of the glass in a single pass with a single machine, without the need to use different machines or change setups. It is an important step forward because it allows to move from an artisanal approach to a more industrial process, making the product more standardized and constant in quality and tolerance. This makes the process faster and more controllable, reducing costs and material handling steps.

Bovone Elettromeccanica Srl

www.bovone.com