Super Spacer® warm edge spacers offer flexibility all along the line

At ZAK 2022, discussions around digitalization, manufacturing automation, innovative window solutions and sustainability will be a constant. “With Window 4.0, the hour of flexible spacers is also upon us”, says Joachim Stoss, Vice President International Sales IG at Quanex. In addition to the topic of energy efficiency, the focus will therefore be on the manufacturing advantages of Edgetech’s Super Spacer® flexible warm edge spacers when processed in automatic production lines.

If not now, when for Warm Edge?

Against the backdrop of current developments in energy prices and climate protection, Stoss places the issue of sustainability at the top of the agenda: “We have to save energy, and we have to do it quickly and everywhere. That’s why we as an industry must also make it clear that there is no way around the warm edge any longer. It is part of the basic equipment of all new insulating glass. Super Spacer offers the best Psi values of up to 0.028 W/mK and enable savings of up to 6 percent on energy costs. Moreover, the costs for the warm edge Super Spacer are negligible. They account for less than 1 percent of the total cost of an installed window. So, what is there to wait for?”

Variability and flexibility

Customized windows have always characterized window construction and insulating glass production. Due to intense competition and great pressure for efficiency, a large part of the industry has made the transition to industrial production. Last but not least, energy requirements, the trend towards large glass surfaces as well as curved and free-form glass are constantly presenting the industry with new challenges.

Super Spacer® flexible warm edge spacers made of silicone structural foam are suitable for manual processing in special designs, automatic application in the edge seal of classic windows with and without internally or externally mounted glazing bars, insulating glass units in structural glazing façades, and for hot and cold curved insulating glass. Silicone structural foam spacers come prefabricated from the roll and are automatically applied along the edge of the glass.

For activities involved in the processing of rigid spacers, such as bending, desiccant filling or joining of the profiles, the investment requirement is very high, especially for small and medium-sized companies. If flexible spacers are applied automatically from the roll, a large part of the set-up time is eliminated and the line is maximally flexible in terms of window dimensions, glass type, number of glazing units and spacer width.

“Super Spacer is set parallel to the millimetre and guarantees a visually appealing, but above all tight edge seal,” Stoss added.

In addition, insulating glass units with Super Spacer® flexible warm edge spacers can be handled, packaged and stored immediately after processing, as the integrated desiccant dries the spaces between the panes very quickly.

According to Edgetech Europe, fully owned subsidiary of Quanex Building Products Corporation, almost no building owner or planner needs to be convinced of the advantages of the warm edge, such as significantly improved energy efficiency, optimized room climate and elimination of condensation in the space between the panes. For this reason, the warm edge spacer is also increasingly coming into focus in terms of production technology, especially since curved windows and free-forms can be designed as multiple insulating glazing exclusively with flexible spacers.

“Due to a shortage of skilled workers and high competitive pressure, many window producers today are faced with the decision in the direction of full automation and, at the same time, the warm edge has become established as an energy-efficient window edge spacer, because in terms of manufacturing technology, they score points over rigid spacers in terms of flexibility, speed and precision,” explained Stoss.

Flexible spacers for precise positioning

New developments such as multi-pane insulating glazing and complex structures with integrated, intelligent functions can only be manufactured economically and precisely with a high degree of automation in conjunction with flexible spacers, the company is convinced. A robot can place the foam-based products in parallel with millimetre precision in a matter of seconds, thus guaranteeing a flawless and tight edge seal. “Automation and digitization will also give medium-sized window producers competitive advantages in the medium term,” Stoss said. “With high-quality products and flexible production that responds quickly to customer wishes and manufacture of smaller series economically.”

Precise application to the millimetre, even on large panes, as is possible with a Super Spacer® flexible warm edge spacer system both manually and automatically, is therefore of particular interest to insulating glass manufacturers and window and façade manufacturers among the ZAK visitors.

Edgetech presents Super Spacer® T-Spacer™ SG at ZAK – Warm edge spacer system for structural glazing and XXL glass panes

“Of course, we will also be presenting our new Super Spacer T-Spacer SG at the ZAK, which has a larger surface area for the application of the primary seal,” said Stoss.

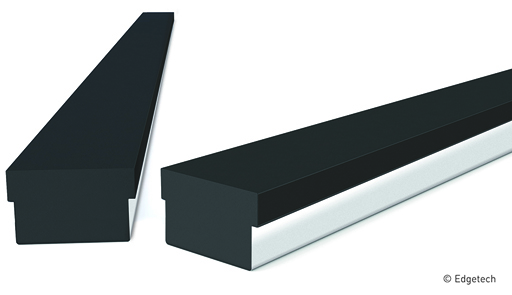

Super Spacer® T-Spacer™ SG was developed for structural glazing and XXL glass panes in order to optimise the durability properties of the edge seal. Here the typical T-shape of the warm edge spacer has been specially adapted to the requirements of automated insulating glass lines for large formats.

Structural Glazing is more than a fashion trend. Thanks to its excellent performance in terms of thermal insulation and life cycle costs, the elegant, translucent façade designs are a growing trend where sustainable building is concerned.

Like all Edgetech products, Super Spacer T-Spacer SG is a metal-free, silicone-based warm edge spacer made of structural foam with integrated desiccant and also has excellent thermal insulation properties thanks to its low thermal conductivity of 0.19 W/mK. The spacer’s composition provides improved shape memory, which is important for the long-term integrity of the edge seal. The resilient structural foam follows the climate-induced movements of the glass and relieves much of the load on the butyl seal. This is an invaluable advantage, especially in climates with very low, very high or highly fluctuating temperatures