Whether it concerns model window panes with extreme radii, portholes that are several centimetres thick or quadruple insulating glass units, hardly any glazing units leave the Porta Glas Design factory without Edgetech’s flexible Super Spacer® Warm Edge spacer system – some 600 kilometres a year – and it is an upward trend.

This is because the main clientele, i.e. the market for high quality tailor-made entrance doors, is growing at a stable rate. At Porta Glas Design is in operation an insulating glass line unique throughout the whole of Germany, in order to facilitate the fulfilment of individual customer requirements even more rapidly and economically.

The mega-trend of customisation is not a new thing. As long ago as 1997 the trend researcher, Faith Popcorn, described the essence of ‘egonomics’: “I stipulate goods and services that are tailored to my own personal preferences”. She was only wrong about one thing, she had suspected that the trend had already peaked back then. Now, in 2019, one does instead sense that the trend is experiencing its second wind.

A wide variety of forms is a must in the front door market

The front door market has, in the premium-price segment, always been a market which focuses on customisation as opposed to mass produced items. The customer has his customised door assembled by a component trader or a carpenter. Wooden, aluminium, steel or plastic, brushed, powder-coated, glazed or lacquered doors in various colours, with glass elements or stainless steel applications, doors that are particularly burglar-proof, thermally insulated or soundproofed – there are virtually no limits to customers’ wishes. The receipt of the order by the front door panel manufacturers sets the downstream delivery chain in motion within the shortest space of time.

The variety of glass elements for front door panels alone is something to behold. The glass processing and refining company Porta Glas Design in Porta Westfalica constantly has around 160 different types of ornamental glazing units in stock. However, in a large number of cases, in-house finishing is employed. “Nothing should be beyond us”, explained plant manager Katja Neumann, “customers’ wishes are only restricted by some physical and economic limits.”

The factory continues to make use of traditional glass making skills. Triangles, ellipses and any freeform designs are mounted here to form insulating glass units. “In the case of these customised and extremely small-format glass sections, only a flexible spacer such as Super Spacer, which can be positioned precisely along the contours, is a viable option,” according to Katja Neumann. In the case of front doors with glass elements, the warm edge with all its advantages represents an additional selling point.

The factory continues to make use of traditional glass making skills. Triangles, ellipses and any freeform designs are mounted here to form insulating glass units. “In the case of these customised and extremely small-format glass sections, only a flexible spacer such as Super Spacer, which can be positioned precisely along the contours, is a viable option,” according to Katja Neumann. In the case of front doors with glass elements, the warm edge with all its advantages represents an additional selling point.

The range of finishing options is also something to behold: laser engraving, customised sandblast matting effects, application of stainless steel, integrated LED light, Swarovski crystals and glass applications, paintwork, facet grinding, Tiffany glass, domed glass or fusing effects and upon request the house numbers, the company logo and customised sample requests can be produced. Every trainee at Porto Glas Design does of course also learn how to manufacture genuine lead glazing.

Automated manufacture of insulating glass production in batch size

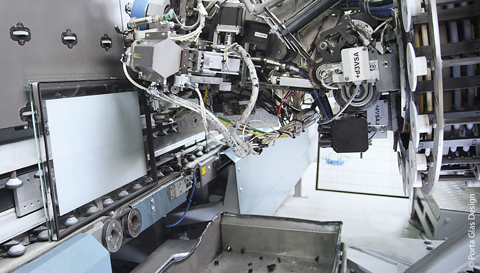

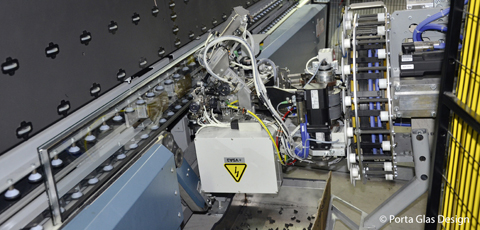

Set against this you will find high-tech in the neighbouring hall, in the form of a LiSEC insulating glass production line that is unique throughout the whole of Germany. It is designed for the economical manufacture of double to quadruple standard glazing units that are up to 100 mm thick.

Depending on the order received and the customers’ requests, extremely small formats ranging from sizes of 130 x 230 mm to large formats of 1,500 x 3,000 mm for fully glazed side sections are run through the machine. The manufacturing process is fully automated, ranging from the washing, drying and sorting to the application of the spacer, the filling of the panes with gas, the compression work and the sealing.

“We only provide the glazing that has been cut to size. All the variable parameters such as the size, thickness, pane structure, required spacers and the jointing compound applied are recorded in the production system, the automatic line subsequently processes each glass format and without any need for manual intervention”, explained Katja Neumann.

Highly flexible solutions are required for this ingenious variant management system. In this way the application robot can access eight different widths of between 8 mm and 24 mm of Super Spacer® T-Spacer™ Premium Plus in parallel without having to change a reel from the stock magazine. The automation is also one of the things that guarantees such a high level of quality. Not even the smallest error in the glass will be tolerated, not even the smallest spot may be visible on the spacer.

Placing their trust in Super Spacer® for the last 22 years

Edgetech has only just celebrated its 30th anniversary. It has been supplying Porta Glas Design for 22 of those years. The glass finisher already opted in favour of Super Spacer® within a year of being founded. Joachim Stoss, managing director of Edgetech Europe GmbH in Heinsberg, is of course delighted about this. “Our Super Spacer proved itself to be extremely flexible in three respects”, according to Joachim Stoss. “The foam-based material composition facilitates its precise application in parallel, and adapts to the pumping motions of the insulating units caused by the weather. Thirdly, it provides the necessary flexibility for the automated manufacture of series and variants.”

All the well-known machine manufacturers offer solutions for the automated production of insulating glass elements using Super Spacer® systems, which also streamlines the entire manufacturing process. Steps such as the cutting to size, bending and filling of the spacers with desiccant are no longer required.