To be the most complete supplier for the international glass industry, enhancing the range of available products and their performance. These are just some of the Fenzi Group’s objectives on a journey begun with the company’s founding in 1941, and which led to the acquisition last year of Thermix, product that rounds out the Group’s range of warm edge solutions worldwide.

Almost a year after the acquisition, Thermix is now produced entirely in Italy and completely integrated into Alu Pro’s operations at its plant in Noale (Veneto,Italy), already a global supply hub for high-performance IG unit spacer profiles. The new system is fully operative, thanks to the 12,000 m2 expansion of the Alu Pro production facility.

The production transfer was completed, as planned, at the end of 2019, with installation of the final lines in early 2020. “We immediately achieved the same high product quality as that of the Ensinger plant in Cham, a major accomplishment gained, in part, due to the support received from Ensinger,” said Alessandro Fenzi, with a note of satisfaction.

“We currently have excellent control of the production cycle and the technology. Thermix is, to all effects, our product and the appreciation our clients have shown is the most immediate demonstration of that,” he continued. “In spite of any possible fears over the change of ownership, we have managed to completely satisfy our clients’ expectations. They were thrilled to see that we had maintained the high-quality standard to which they were accustomed thanks, above all, to our extensive, decades-long knowledge of the industry and our unique specialization in glass,” Fenzi concluded.

The trend remains positive. The fast-paced warm edge market – high-efficiency technology to improve living comfort in buildings and, thus, the quality of life of its residents – is leading the most qualified producers to increase production levels, and that is precisely what Alu Pro has been doing for years. Orders for the new product, already a well-known market favourite, are proof of that.

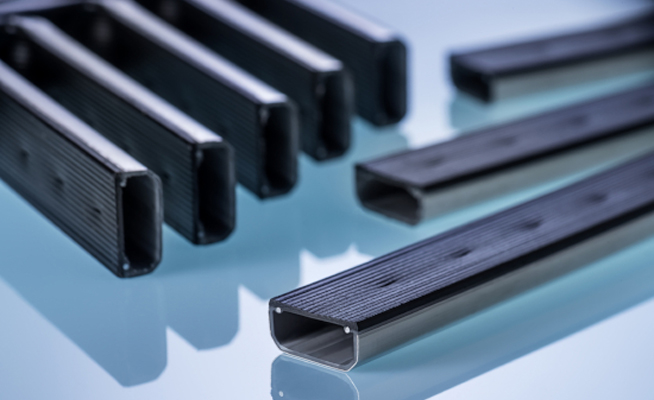

In fact, Thermix Tx Pro is optimally positioned among warm edge profiles in terms of performance, stability and ease of processing. Made with a special technopolymer and stiffened with two heavy-duty stainless-steel wires, the spacer is partially coated with a super-thin stainless-steel foil that provides bonding support for the sealants and acts as a barrier against loss of gases, allowing the entire IG unit to effectively block heat dispersion.

These specific features and perfect compatibility with Fenzi sealants for IG units make Thermix Tx Pro a top-quality product that completes the range of warm edge solutions offered by the Glass Alliance network.

With 13 production and sales units around the world, the Fenzi Group serves its international clients from multiple distribution centres on all five continents. Essential to its global strategy, this network has led the group on its path to success which, even in the midst of the Covid-19 pandemic, has not lost its stride.

“Thanks to winning strategies that have consistently been based on long-term development plans, the Group’s foundation is solid,” stated Fenzi, who concluded, “The trying months of lockdown have not dampened our enthusiasm or the company’s plans. Thanks to the firm commitment of our entire value chain – from our employees to all of our partners – the health crisis has spurred the initiation of efficient synergies and new business models.

“Despite the uncertainty of the times, our dedication and positivity in coping with the challenges of the coming months is unwavering, with new investments and renewed confidence in an industrial sector rife with potential and vitality.”