Forel has responded to 2020 with new investments and projects: the main production site is expanding, a new commercial branch will soon be inaugurated in South Africa, the range of solutions for double glazing has been completed with a specific line for the assembly of the panels with thermoplastic profiles, and important new investments have been made in the Service department.

|  |

INNOVATION

“In the coming months, four important projects will be launched, to which we have dedicated considerable efforts and resources, to establish ourselves even more in the global industry of glass manufacturing automation,” comment Fortunato and Riccardo Vianello, owners of Forel. “The projects we are announcing today can be summarized in four words: technology, productivity, internationalization and assistance.”

As for technological innovation, the Thermoplastic Spacer Applicator Art. TA is in presentation, enlarging the Forel range of solutions for spacer application.

“With the Thermoplastic Spacer Applicator, Forel developed innovative solutions for this kind of processing, optimizing not just the spacer application but all the process of assembly of the insulating glass unit,” says Fortunato and Riccardo Vianello. “Our thermoplastic spacer IG line is indeed a solution with unique features, which already drawn the attention of many customers.”

EXPANSION

Forel’s business volume has been growing steadily for over ten years: to cope with the large number of orders, it was necessary to invest in new resources involving the whole company and all business aspects… and also in the production space.

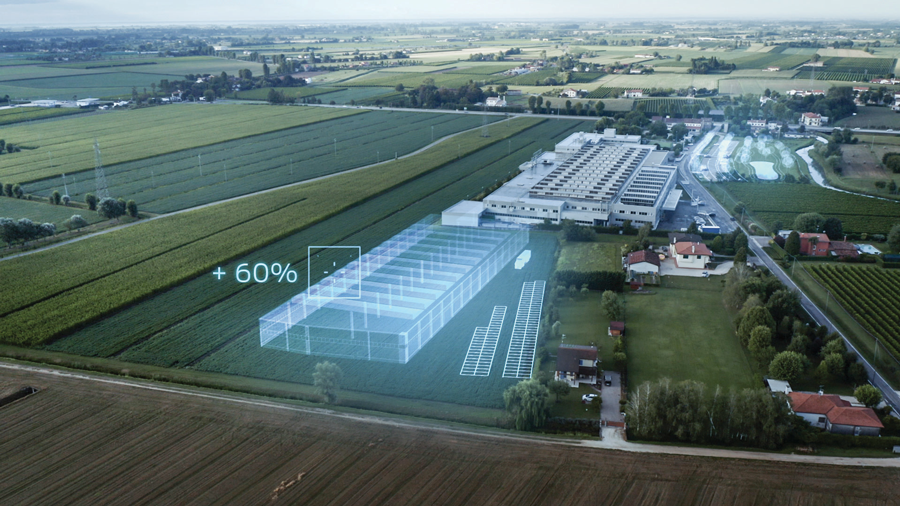

“In its history, Forel has always enlarged its presence in the market, year by year. As a consequence, we need to constantly increase our production area. The next investment, indeed, will be remarkable: Forel’s production site in Treviso will be enlarged by more than 60 per cent.”

Thanks to this operation, it will be possible to process a greater number of orders at the same time, thus avoiding moving a part of the production to other sites: this will result in greater efficiency and faster production times, while ensuring the same quality of the finished product, strictly ‘Made in Italy’.

BUSINESS GROWTH

Quality is the value which has allowed Forel to compete on international markets. With a commercial network of 31 agencies worldwide, the company currently exports to 72 countries, but never stops expanding its horizons, in search for new opportunities. In 2020, collaboration was formalized with the South African manager Afam Ike, a professional with over 20 years of experience in the glass manufacturing automation sector. From this partnership, Forel Africa will soon be born: a new branch based in Johannesburg to further develop the brand in the African continent, both in terms of commercial presence and after-sales management. Afam Ike will take on the role of CEO.

“I am honoured to join the Forel team, a company whose commitment, business philosophy and innovative technology I could immediately appreciate,” commented Afam Ike. “In Africa, the glass market is showing a sharp growth, but African glassmakers need reliable partners that bring added value to their business, especially in after-sales: many companies today suffer from the lack of empathy from current suppliers, the poor preparation of assistance staff, the exorbitant cost of spare parts and software updates. Today Forel offers the best technical assistance service on the market, which aims to amortize customer expenses, optimizing the cost/benefit ratio. Forel is a partner who cares about technology sustainability and, most importantly, who listens, understands and responds to the different needs of the African market.”

ASSISTANCE

Customer assistance, which has always been one of the company’s priorities, is at the centre of new investments. Forel Service team, which includes on-site staff, travelling technicians and spare parts shippers, is being upgraded. From a technical point of view, remote assistance has been enhanced with a series of new additional augmented reality technologies, offering the customer the best support in troubleshooting and maintenance. Technical training, both for Forel staff and for the maintenance technicians of agencies and customers, have always been at the centre of a vast programme of lessons and demonstrations, and has also be enriched with new multimedia and interactive tools. This ensures the best preparation and a continuous updating of all the technical intervention staff of the Forel network.

Forel SpA

www.forelspa.com