Industry 4.0 is the ‘buzz word’ of today’s industry and the glass sector is moving fast to adapt to and apply this new level of automation. Forvet gives us an idea of how, thanks to new company reorganization and investments, it provides glassmakers with machines and systems for a total management concept.

|  |

In the past, the simple implementation of automation technology in a company put it a step ahead of the competition. These days, business leaders everywhere understand the need to know not if we automate, but how we do it.

Automation is the future. Automation accelerates progress on projects that increase revenue, serve customers more effectively, and save on costs. Automation might sound like something that belongs in a large enterprise, but businesses of all sizes benefit from it. More automated processes limit the impact of labour costs and improve efficiency.

NOT JUST A SIMPLE OFFER OF DRILLING AND EDGING

As confirmation of this trend, Forvet has carried out company reorganization, where new managers, new engineers and new technicians have been hired to cope with company expansion, along with new buildings to double production capability.

Important investments have also been made toward new conceptual research and development, where the specific Forvet machine supply is only a part of the elaboration of projects.

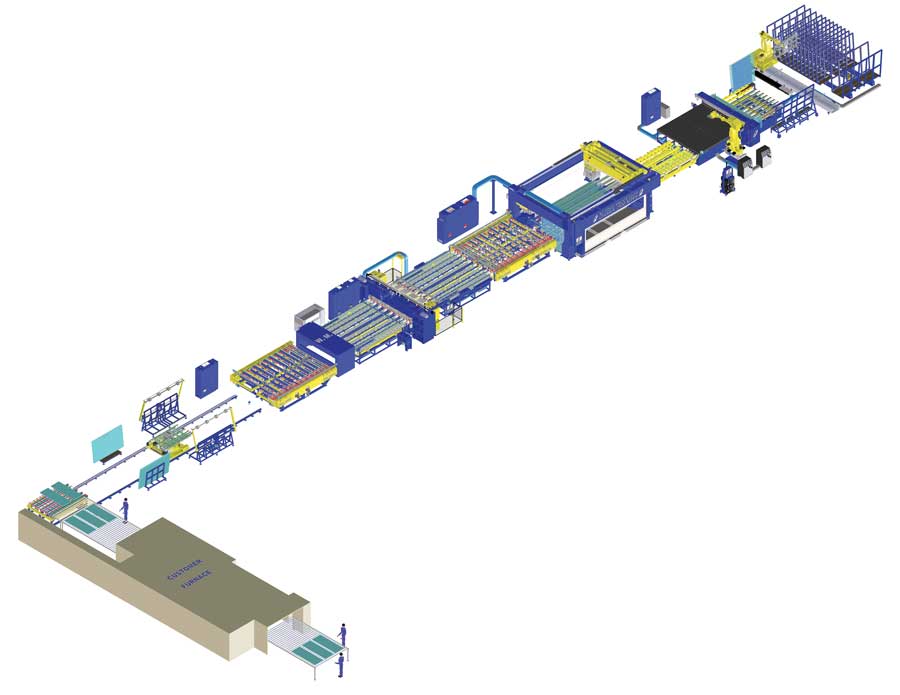

The approach the company is proposing goes far beyond the simple offer of drilling or edging technology, even if unique. It analyses the entire series of glass company needs and generates proposals that include glass flow optimization, implementation of sorting systems with new concepts, ideas and high technology.

FORVET, ITALIAN EXCELLENCE THAT ALLOWS MODERN GLASS FACTORIES TO REALISE DREAMS

Forvet builds glass working machines and integrated solutions that are unique in terms of their performance innovation, technology, driving passion and benefit. All this has to be sustained by solid and complete knowledge of glass process know-how, and supported by sophisticated software controls.

Forvet Automation department has experienced software engineers born and matured in the glass field, granting the achievement of any project size, regardless of its complexity. The deployment of automation technologies leads to a range of performance benefits for glass companies. These benefits are varied, depending on individual cases, and potentially very substantial – in some cases, considerably larger than cost reductions associated with labour replacement. They include, but are not limited to, greater throughput, higher quality, improved safety, reduced variability, a reduction of waste, and higher customer satisfaction

AUTOMATION ALSO MEANS CAPABILITY OF GLASS HANDLING AMONG PROCESSES

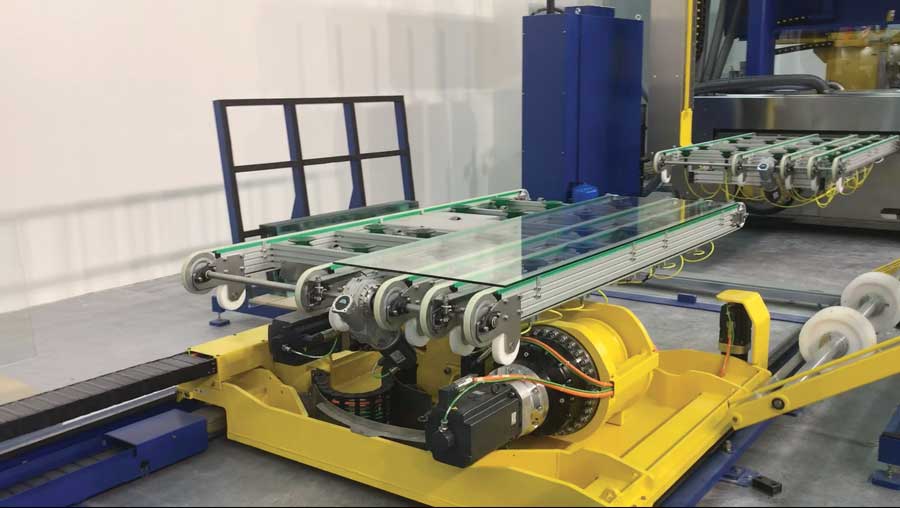

The integration between Forvet edging equipment Chiara and CNC drilling centres Francesca is well known: Forvet today is also providing all previous and subsequent integrations.

Forvet automated and integrated machines are designed to perform a number of operations at the same time, which means there is no need to move the glass after each stage of production, as the finished products can be delivered directly to storage without any human intervention.

Connecting the equipment to business systems will greatly reduce the effort which is required to create production status/reports.

Implementing automation will help keep employees safe as there will be no need for them to enter automated lines, except for maintenance work.

LABOUR MANAGEMENT

Effectively managing labour, such as employee leaves and absences, has a significant impact on overall employee productivity. Accurate staffing, along with the support of temporary workers, ensures that workflow and production levels remain consistent when some employees are absent for extended periods of time.

Automated equipment enables to manufacture quality glass in the most efficient way possible. Automations enable companies to improve performance, by reducing errors and improving quality and speed – where productivity acceleration is sorely needed, especially as the share of the working age population declines in many countries. At a microeconomic level, businesses everywhere will have an opportunity to capture benefits and achieve competitive advantages from automation technologies, not just from labour cost reductions, but also from performance benefits such as increased throughput, higher quality, and decreased downtime.

GETTING READY FOR TOMORROW – TODAY

The world is changing all around us. We must look ahead, understand the trends and forces that will shape our business in the future and move swiftly to prepare for what’s to come. We must get ready for tomorrow, today.

However, when it comes to inventing new equipment and unique solutions, it’s not only excellence that greases the wheels of innovation: it’s risk, audacity, and singularity that make the difference!

Forvet SpA

www.forvet.it