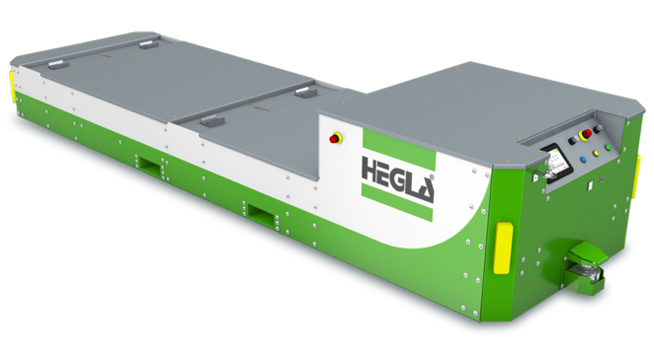

HEGLA‘s Automated Guided Vehicles perform various tasks independently, with automated guiding and in tune with production cycles, for instance transporting mobile storage racks and A and L frames between the cutting and the individual processing stations.

Features

- Continuous, optimised flow of materials

- Transparent processes with real-time monitoring

- Reliable, specialist transport of large quantities of glass

- Easy automation adapted gradually or completely to suit your needs

- Automatic or manual loading and unloading of glass

- Suitable for both EU and US-type mobile storage racks and A and L frames

The mobile storage racks can be loaded automatically or manually. Once this is done, the AGV starts its journey to the loading point in response to a command from the operator or the production software, lifts up the mobile storage rack and uses natural navigation to transport it to its destination. As soon as the AGV’s scanners detect an obstacle on the route, the vehicle comes to a stop. The mobile storage rack is set down in the unloading or sorting station. Depending on the configuration of the automated guided vehicle and what optional equipment it has, it can then be moved to its next destination or stopped to recharge its batteries.