Many companies in the glass-processing industry have enough machine and system capacity to process their customer orders.

But a lack of skilled workers, processes that are not optimally harmonised, the need for lots of in-house coordination, and rising delivery date and cost pressure can lead to bottlenecks – even at companies that otherwise have everything under control.

For such critical aspects, the integrated consideration of processes, machines, employees, communication, and products is an approach that provides digital support for processes, uses existing means even more efficiently, and focuses on optimising the flow of materials.

Words like ‘smart factory’ and ‘digitalisation’ are the current buzzwords used to describe this development process, but the glass industry has been aware of it since before these terms were even coined. Early on, CNC machines were used to simplify and accelerate the glass-cutting process. Automated loading was adopted in order to supply the cutting lines with glass in precise synchronisation with the cycle and meet the operators’ needs. Next came residual sheet handling systems such as ReMaster, which saves resources, helps to preserve the quality of the glass, and rescues employees from a strenuous, time-consuming activity. Sorting systems were ultimately the logical consequence of these developments, and their overarching concept led to the glass flow being improved and homogenised across the entire cutting line.

The number of panes and pressure caused by fast cycles requires smooth processes

The number of panes and pressure caused by fast cycles requires smooth processes

Automation was the key concern in process optimisation for many years, but the continuous stream of new opportunities provided by digitalisation has increasingly expanded this focus to include other areas.

“The conversion of production into an integrated, overarching process will improve the transitions between machines, the way they interact with operating personnel, cycle times, and the flow of materials,” said Bernhard Hötger, Managing Director of the HEGLA Group. “More and more new areas will be included.” In order to tap the entirety of the systems’ potential, the rising level of automation requires more and more coordination among the tasks and dependencies of the internal glass logistics in the production hall. The term ‘shop-floor logistics’ aptly describes the change process affecting conventional production facilities. In many cases, up-to-date equipment no longer automatically means that machines are responsible for production process efficiency. Instead, the key is how quickly and in precise synchronisation with the cycle the glass is available at each processing station. The number of panes and the pressure caused by fast cycles require smooth, precise, and transparent material delivery in order to reduce or avoid downtime caused by manual handling or a lack of glass.

Software as a key factor in the success of integrated production

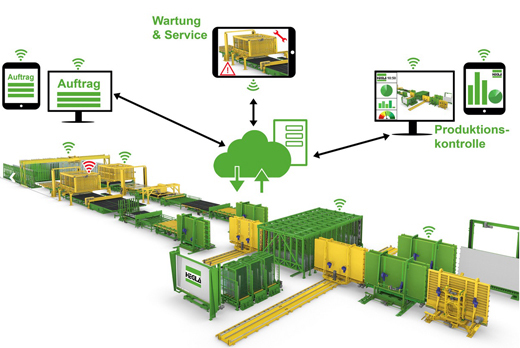

Software is a key factor in ensuring that the integrated transformation of production is successful. Depending on the control concept and integration depth, it should digitally map not just the production process and its component parts, but also individual panes, along with their flow through the production facility. Of course, this requires the ability to select, acquire and compile the required data and key indicators and turn them into information.

“These data enable us to simulate the processes in advance, define ideal processes, and derive potential areas of improvement,” explained Dr Jan Schäpers, Managing Director of software specialists HEGLA-Hanic. Although more or less all of these data were available in the past, they primarily took the form of theoretical maps of reality that were based on planned values and probabilities. That is why one of the aims of the smart factory is to map processes accurately and in real time, using sensors to query systems or record and track laser-marked panes via scanners, for example. Once it has become possible to make target/actual comparisons based on the data, processes can be optimised in even greater depth: capacity can be adjusted and any bottlenecks that could be resolved by further automation identified. Another objective of the analyses could be to find out where processes can be changed or optimised in order to deploy existing personnel at the places along the production line where they can contribute the most towards the company’s value creation based on their manual or technical skills. At the same time, the machines can continue to assist the employees with their work – whether it’s by providing help with workflows, data referring to orders, notes on controls, information on system states, or in general, by enabling even user-friendlier, more intuitive control.

As digitalisation and connectivity increase, ever more opportunities for digital support and process steering will emerge. In future, operators will no longer have to rely exclusively on local data access at the system or via control panels. Instead, they will be able to perform such tasks as triggering a new order for damaged glass, determining where a glass rack has been parked or which process comes next, retrieving maintenance information, reporting a malfunction, or re-ordering supplies – all using an app developed by HEGLA New Technology.

The level of transparency and precise knowledge of the process also give production management and work preparation a new degree of flexibility. Orders can be monitored from a desktop or the app and, depending on the data storage methods used, can be reconstructed years later. It will also be possible to adjust capacity and production planning in real time. Rush orders in particular will benefit from greater flexibility: it will be possible to prioritise or re-plan and track panes and finishing treatments in accordance with customer requirements.

Data provision via defined, open interfaces

These scenarios of networked, integrated production are gradually becoming a reality thanks to the ever-increasing volume of data available and insights into processes. In future, this will make it even more important to have joint, defined, and open interfaces for machines and software in order to make such in-depth networking between quality providers of machines and software both possible and reliable. A German Mechanical Engineering Industry Association (VDMA) steering group is working together with HEGLA-Hanic, Grenzebach, and A+W on a joint OPC UA platform (Open Platform Communications Unified Architecture) to create the foundation for these processes.

The form and extent to which production departments – or even entire companies – must adjust to or can benefit from the future demands of the smart factory varies from one case to the next. Depending on their product ranges or market niches, companies will have different needs. Dr Jan Schäpers advises companies to perform an exhaustive analysis of their machine parks, existing workflows and software, communication, and information requirements, and to weigh up the costs of the results against the benefits. For complex production processes with high-priced, time-consuming glass pieces, for example, it can make sense to use tracking via laser marking. Meanwhile, small companies may benefit from the use and integration of state-of-the-art, future-orientated ERP software with access to the machine level in conjunction with an app. In many other cases, alongside further automation in the form of driverless transport systems running between individual processing centres, for example, the expanding options for remote maintenance and the increasing number of sensors in machines will prove attractive areas of development. By means of continuous queries, systems with this capability will be able to monitor technical states and predict the need for pending maintenance or wear part replacement.

The gradual process of determining which areas are relevant and offer the best benefits will make a profound level of integration and connectivity possible. This could encompass operations and companies in their entirety and offer them maximised, organically expanding potential for controlling, optimising, and completing all their processes, from the receipt of orders and all their commercial processes to production planning and control.