The amount of glass on buildings continues to increase: be it transparent façades and multiple IGUs on new buildings, or windows and panes that are replaced on existing properties at the end of the product life cycle.

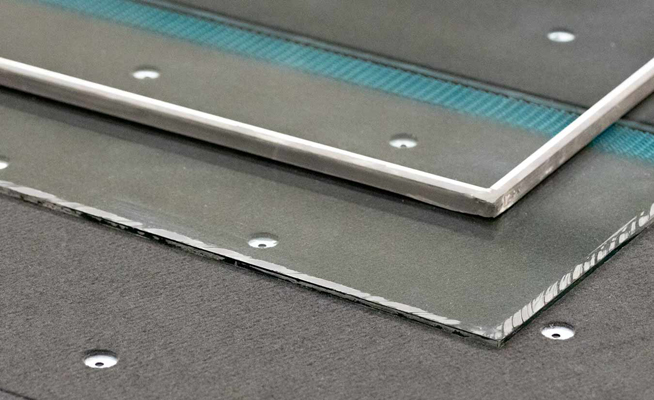

With the IG2Pieces assembly line technology, HEGLA has developed a solution that can automatically separate insulated glass. At the same time, the company offers a handling concept that retains the purity of the raw material and improves revenues, or enables panes to be reused as such.

Dealing with imperfect panes and used glass sustainably

To ensure that glass panes remain usable for a range of applications, the aim was to release the individual panes from the spacers reliably, cleanly and without damage, while maintaining high productivity.

The measurement of the ISO dimensions and the insulated glass structure is fully automated. Once the glass has been removed from the laminate, it can be recycled without any loss of raw material quality. Just like the panes, the unimpaired spacers, including the intact desiccant, are conveyed to a separate system for disposal or recycling.

Type-specific float glass yields financial advantages

Separated recycling of the individual types of glass yields advantages compared to mixed containers. When panes are professionally separated, this generates added financial value.

The impact on the environment is also positive: the panes find their way back to the float tank to close the material circuit, while preserving the quality of the raw material. Further, one kilogram of float glass that is produced from used glass generates around 0.3 kilograms less CO2, compared to a classic glass mixture.

Reuse and repair

Alongside type-specific recycling, the reuse of undamaged panes is yet another option that increases the recycling rate. If, despite all precautions, there are impurities or surface defects in a freshly produced insulated glass laminate, the individual pieces can be cleanly removed and the defective pane can be disposed of, if necessary.

If repairs cannot be made during the ongoing production process or if no special-purpose cut is available, there is a third option. The clean application of butyl and sealing of separated glass can be planned for follow-up orders and cut to smaller dimensions. Applications here include LSG, high-quality, refined glass or special-purpose glass that is no longer available.