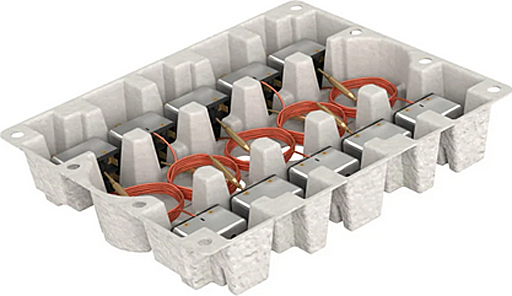

The transport of glass products is even safer and plastic can be completely dispensed with: According to HEINZ-GLAS, the fibre cast packaging developed together with the Cologne-based company PAPACKS Sales GmbH and with COTY has more than fulfilled the expectations placed in it.

The most important thing the Upper Franconian bottle manufacturer emphasizes is that the three-dimensional transport bowls are more dimensionally stable and shock-absorbent than their plastic predecessors and guarantee improved protection. The innovation is based on 100 percent renewable fibres such as cellulose from trees and industrial hemp. This alone reduces the CO2 footprint by a factor of four.

The most important thing the Upper Franconian bottle manufacturer emphasizes is that the three-dimensional transport bowls are more dimensionally stable and shock-absorbent than their plastic predecessors and guarantee improved protection. The innovation is based on 100 percent renewable fibres such as cellulose from trees and industrial hemp. This alone reduces the CO2 footprint by a factor of four.

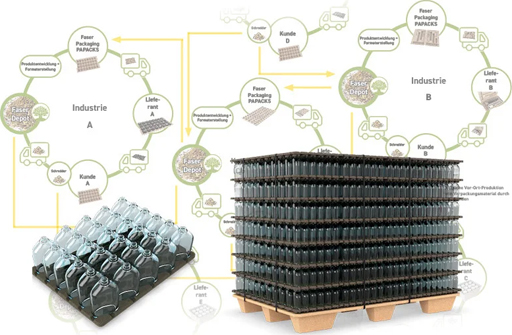

According to the zero-waste principle, the cast fibre transport packaging produced can either be recycled as waste paper in the green circulation system or decompose as biocompost within 6 weeks.

Of course, cast fibre transport packaging is robot-compatible, can be stacked to save space and allows easier handling when assembling the pallets due to the reduced number of components.

The mould concept for manufacturing the cast fibre transport packaging was developed and patented over the years based on PAPACKS 3D printing technology. The fibre casting moulds coming from the 3D printer can therefore be adapted to individual customer requirements in a cost-efficient and flexible manner.