Henry F. Teichmann has been providing turnkey projects that include engineering, procurement, construction and project management to clients worldwide for over 70 years. Projects of the company, some aspects of which are described in this article, cover a multitude of aspects of the glass industry: from complete float, fiberglass and container plants, to those for borosilicate tubing, tableware and pressware, pattern glass, environmental waste, lead crystal and hand glass.

|  |

Henry F. Teichmann, Inc. is a global engineering, procurement and construction (EPC) company dedicated to designing and building high quality and efficient glass manufacturing facilities. For more than 70 years, global glass makers, corporations and developers have trusted Henry F. Teichmann, Inc. to bring their projects to life. Headquartered in Pittsburgh, Pennsylvania, with regional offices in the UK, China and Singapore. HFT employ engineering, and construction professionals and craftsmen worldwide with the commitment, expertise, and passionate work ethic that is the cornerstone of the company’s success and continued growth.

Over the decades HFT has contributed to their clients’ ability to realize extraordinary achievements. In doing so, they have not only built a diverse portfolio of lasting, high quality production lines and glass manufacturing facilities, they have built a reputation for providing solutions and have constructed over $3.5 billion in installed value for global glass makers. From start to finish, HFT can plan, design, and construct projects anywhere in the world.

Long before ground is broken, HFT apply their accumulated construction knowledge and business sense to understand the purpose and mission of the project to establish an agreed upon approach that will bring the vision to fruition. Early engagement can have an immediate impact through proven cost controls, global sourcing, and schedule management, providing clients with a greater opportunity for savings and a successful project outcome.

ENGINEERING SERVICES

One of the most important objectives of HFT’s engineering services is the development of cost budgets that synchronizes with client programs and expectations. HFT’s engineers and estimators specialize in cost estimates from the initial programming phase into detailed design and procurement, through the construction and execution phases. Through a mix of inhouse specialist designers, engineers, glass process experts, estimators, and construction leaders, as well as strategic industry partnerships, and other project team members, HFT develop the best engineered solution to meet productivity and quality requirements, within the budget constraints and program needs of the client. Engineering services include a targeted focus on the critical details important to the success of a project, such as site development costs, process equipment, melting technology, structural and utility systems analysis, material selections, cost saving alternatives and development of project schedules, and execution plans.

Involvement during the initial phases greatly influences glass makers’ ability to recognize savings and maximize their budget potential, all the while minimizing project risk through early identification of cost drivers. Constructability design reviews ensure that scope creep is eliminated and that the project schedule is maintained.

The sooner HFT gets involved on a project, the sooner the engineering, estimating & procurement teams, glass process specialists, and project support staff can get to work saving glass makers money and reducing project risks. By helping make more cost effective decisions in the engineering and schematic design phases, HFT can help save a significant amount of money while still delivering the quality and efficient end project envisioned when beginning the project.

PROCUREMENT SERVICES

Through decades of designing and constructing glass plants around the globe, HFT has developed an extensive database of vendors and manufacturers both nationally and internationally who are able to provide both cost effective and high quality proven product supply through direct acquisition agreements.

Because construction material and process equipment acquisition can account for a significant percentage of a project’s overall cost, this value added service is an integral and vital part of any project. HFT’s complete procurement approach evaluates and provides projects with multiple options for its stakeholders, allowing clients the ability to make the best and most informed decisions.

CONSTRUCTION

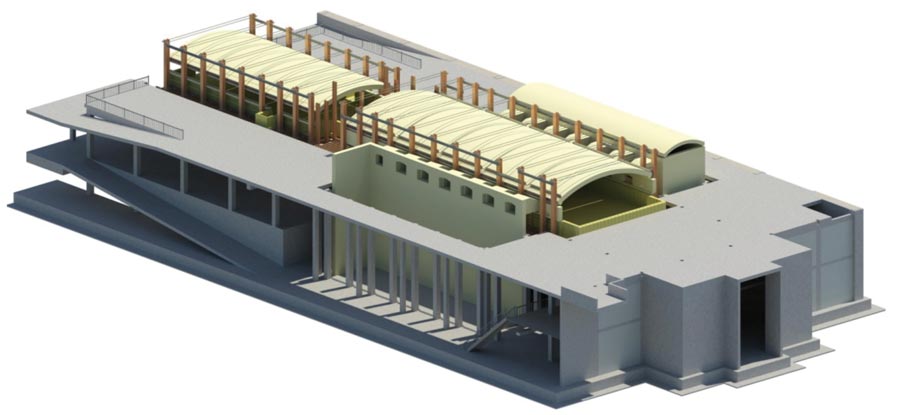

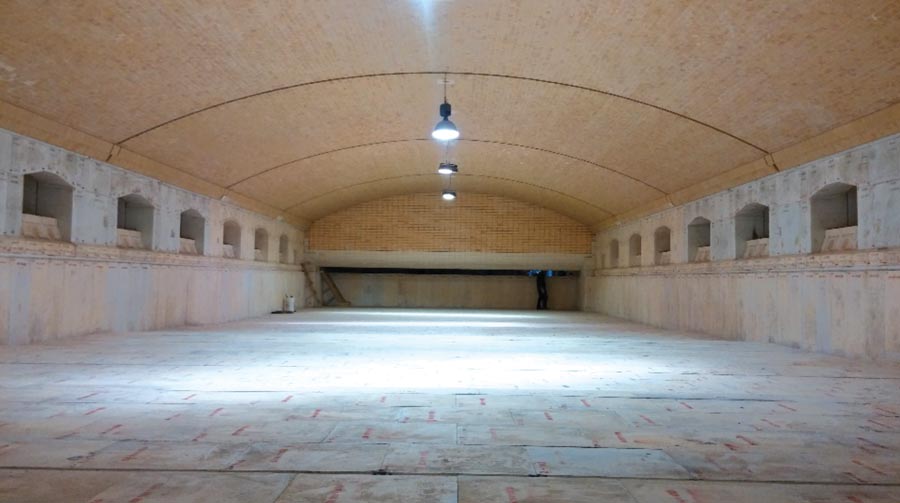

HFT has the know-how to perform all kinds of construction and installation, including steel structures (inclusive of buildings, furnace, silos and forming areas), concrete (pre-cast and cast in place), refractory brick, civil/excavations, utilities & infrastructure, and process equipment from raw material reception/mixing, though glass melting, forming and into packaging. As one of the most experienced General Contractors in the glass industry, HFT delivers projects for all types of construction.

HFT’s operational excellence is focused on a complete project execution plan, including well-established systems, facilities, processes, and in-place relationships to efficiently procure and mobilize experienced manpower, equipment, and materials within the United States and other parts of the globe to support projects, in even the most remote and challenging regions of the world. Below are some of the many operational aspects we integrate into our complete client solution approach:

As a core business value, EH&S is at the forefront of HFT’s operational best-practices and communications. HFT work with suppliers, subcontractors and clients to promote responsible health and safety practices. In this way, HFT sets an example of leadership in the field of health, safety and environmental management, and will promote resource conservation, the reduction of waste and pollution prevention.

POWER SOLUTIONS

HFT’s problem-solving approach has led to them recently expanding their portfolio to offer EPC project solutions in other rapidly growing markets, one of which is off grid power generation solutions. For the growing microgrid market, HFT’s power solutions team provides all manner of projects including waste heat recovery, combined heat and power, demand response, resiliency, storage, solar, and renewables. This includes sourcing any available grants or public funding to offset the capital requirements of project implementation.

Leveraging the most advance technology and diverse project experience, HFT combines sophisticated techniques with a strong work ethic to streamline communications, reduce complexity, manage risk and achieve the best project outcomes. Through this approach HFT team members have a combined experience of installing over 5,000 MW of successful power generation projects. HFT is also a proud contributing member of the Combined Heat and Power Alliance.

Visit our new look website at www.hft.com to learn more, and contact us today to talk about your next project.

Teichmann Henry F. Inc. – HFT

www.hft.com