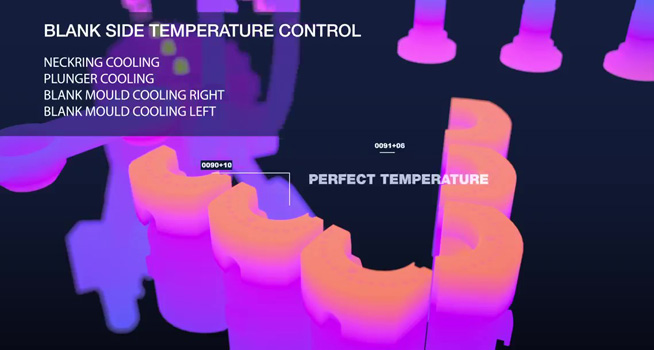

Heye‘s TIS – Thermal Image Sensor is a measuring system designed to monitor temperatures on the blank side. Temperature monitoring helps to prevent bottle defects and enhance process stability, leading to reduced job change times.

The TIS consists of an IR-camera located in a protective housing with internal water cooling. It is mounted in a carriage on the blank side operating channel and moves from section to section along the machine. When the TIS reaches the measuring position, it captures four images within a section cycle on the parison and the mould parts: blank mould, plunger and neck ring.

The TIS is equipped with its own drive. The intelligent travel program recognizes lubrication cycles, causing the TIS to move away from the operator, on the one hand to avoid obstructing their work on the machine, and on the other hand to prevent contamination by lubricants. When combined with the Heye BlankSideRobot, the TIS is synchronised with the robot’s lubrication cycles.

The Heye TIS is another part of the various automation solutions Heye is offering to customers.