ITALCARRELLI® is continuing to improve logistics in float glass factories with its most recent systems for LGV inloaders: BES, RDS & RIS. This article gives us an idea of how the company supplies the most important global float glass producers and processors with its tailor-made handling solutions.

|  |

For accurate, flexible, and efficient logistics results, today’s glass-manufacturing plants rely on high-performance handling machinery, thus increasingly moving towards smarter, connected, and autonomous systems.

With its tailor-made handling solutions, ITALCARRELLI® supplies the most important float glass producers and processors all over the world. International customers who are constantly growing and changing and therefore always attentive to the most modern technological and cutting-edge equipment.

In recent years, the company’s Glass Division and R&D department have constantly focused on product innovation, studying increasingly performing handling solutions and making important investments in automation, development of autonomous guided vehicles (AGV), and correlated services.

LGV TECHNOLOGY

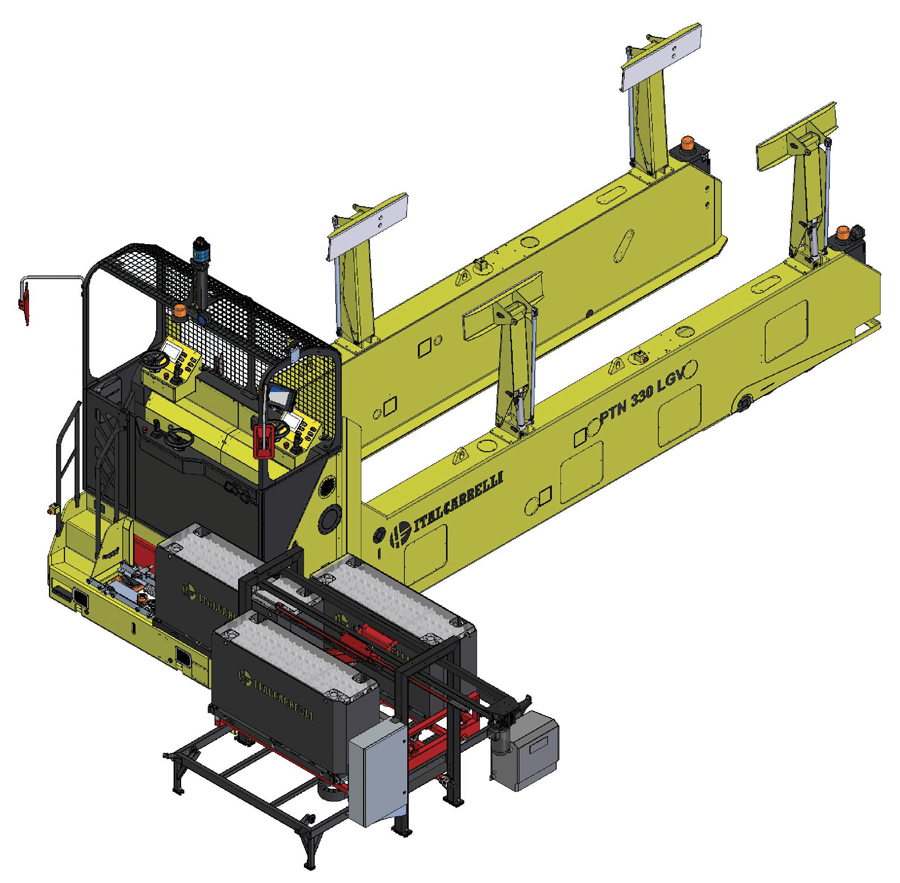

In the glass industry, Italcarrelli mainly supplies machines based on LGV technology (Laser Guided Vehicles). The LGV consists of the triangulation of the position through a laser scanner monitoring its position compared to fixed reflectors installed in the warehouse. This guidance system provides excellent accuracy, it does not require any particular installation on the facilities, and the routes can be easily modified. Continuing to revolutionise float glass factories logistics, Italcarrelli engineers have developed the BES, RDS and RIS for LGV PTN inloaders, which operate without operators on board.

BES (BATTERY EXCHANGE STATION)

The BES (Battery Exchange Station) is a patented system that allows automatic recharging and replacement of the battery onboard the LGV. Thanks to this system, the battery once discharged can be replaced automatically without the intervention of any operator. The low battery LGV will automatically move to the BES to swap the battery with a charged one and the whole operation will take about 4 minutes. Thanks to BES, Italcarrelli has considerably increased the operation of its LGV machines, as it is no longer necessary long stops for battery

recharging. The BES station is also available for standard onboard operator machines.

RDS – RACK DETECTING SYSTEM

The RDS, an acronym for Rack Detecting System, is an innovative localization system that allows tracking all information about the load – i.e. presence of the load, an estimate of the glass width, pack numbers, and position on the rack, rack type – for safer handling. It can be installed on both AGV and manually guided machines, to help the operator in his manoeuvring operations. The inloader is equipped with various electronic sensors to provide all the data: encoder, photocells, and ultrasonic sensors. Thanks to RDS, the system not only detects if the rack is present but also starts an automatic slowdown of the machine and stops it to prevent from hitting the rack during loading.

RIS – RACK IDENTIFICATION SYSTEM

Moreover, the machine can also be equipped with RIS (Rack Identification System) which allows scanning a barcode or reading an RFID tag with the information about the racks and communicating it automatically to the warehouse management software or ERP, so it is possible to know at any time the exact location of glass and racks. Italcarrelli paves the way for a new generation and increasingly technologically advanced machinery and accessory technologies for handling float glass. With the highest standards of safety, quality and continuous developments in robotics, software and services in mind, it aims to provide ever-greater customization of the machine and its features.

Italcarrelli Spa

www.italcarrelli.eu