Monitoring the internal profile of wine bottles is essential in a glass plant, whether done manually or automatically at the hot-end or cold-end. Konatic has developed a simple solution bridging the gap between manual measurements and sophisticated all-in one laboratory devices.

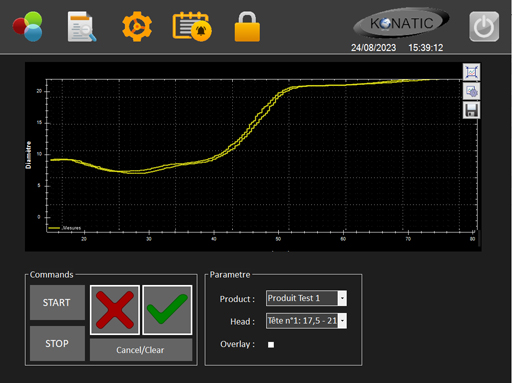

This solution is called Innerscan: a robust, user-friendly device equipped with a motorized head and open protocols for recording and transferring data to MES automatically.

At its core, Innerscan boasts a distinctive advantage: swift and precise measurements of a bottle’s profile, even when freshly produced and at temperatures of up to 100°C.

Innerscan is already operational within manufacturing facilities, and its framework is based on previous machines developed for hot-end and laboratory environments, such as Precision Reader (datamatrix reader at hot-end) and NANO (hot-end coating measurement without index fluid in the laboratory).

Innerscan is already operational within manufacturing facilities, and its framework is based on previous machines developed for hot-end and laboratory environments, such as Precision Reader (datamatrix reader at hot-end) and NANO (hot-end coating measurement without index fluid in the laboratory).