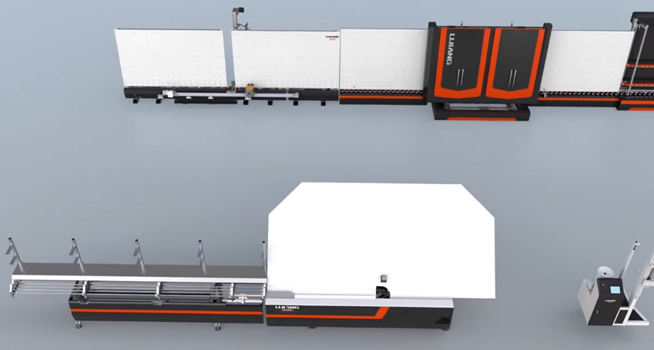

These are 8 steps to understand the process of a LIJIANG Glass‘ insulating glass machine, of course the company can also provide user manuals.

- Bending of aluminium spacers: First, cut and bend the aluminium spacers into a shape of appropriate size according to the glass processing size requirements. This step is usually completed by automated bending equipment to improve production efficiency and reduce manual errors. At the same time, laser coding can be performed according to the OA work order system to identify the model.

- Filling of aluminium spacers: After the aluminium spacers are bent, the aluminium spacers are filled with adsorbents. Generally, a 3A molecular sieve is used as the adsorbent for filling.

- Low-E film layer detection: The film layer is detected through the Low-E Glass photoelectric detection switch in the feeding section to effectively prevent the Low-E Glass from being placed upside down.

- Washing and Drying: The cut glass blocks will go through the washing process to remove dirt, grease, and other impurities on the surface to ensure that the next process can proceed smoothly. Glass washing usually uses an efficient washing and drying machine, which can complete the cleaning of large quantities of glass in a shorter time.

- Inspection: The washed glass blocks need to undergo strict quality inspection to ensure that they meet the standards and requirements. The inspection process is usually carried out by manual visual observation, which can detect the flatness, thickness, surface defects, and whether the glass is clean.

- Assembly: The glass blocks that have passed the inspection will be sent to the insulating glass plate pressing segment for assembly. The insulating glass machine will automatically place two or more pieces of glass at the required interval and inflate them.

- Sealing: The assembled glass undergoes a sealing process to ensure that the gas or air in the insulated layer does not leak. Sealing generally uses high-efficiency sealants, such as hot melt sealant or structural sealant, and fully automatic sealing robot lines for sealant application.

- Inspection: Finally, the insulating glass is inspected again to ensure that the quality and performance meet the requirements. For example, glass appearance inspection, sealing test, thermal performance test, etc. can be carried out.