The 32nd China International Glass Industrial Technical Exhibition (China Glass 2023) opened on 06 May, 2023. In the large exhibition booth of NorthGlass, sales elites from all the NorthGlass business units gathered to share the latest technological products and solutions of NorthGlass in the field of deep processing glass and building wall materials, presenting an unprecedented feast of innovation.

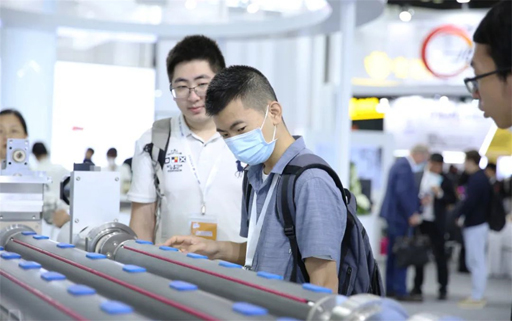

NorthGlass’ booth welcomed a large number of visitors. In the first two days, more than 2,000 customers were received and multiple orders were signed. NorthGlass sales and customer service representatives had in-depth technical exchanges and business negotiations with customers from all over the world. Meanwhile, they developed effective solutions for customers’ practical problems and business conditions in the production process. Through communication and technical demonstration, customers could have a more intuitive experience of the intelligence, informatisation and digitization of NorthGlass professional equipment.

At this exhibition, NorthGlass has launched the fourth generation advanced series (A-series) tempering furnace, which adopts a professional temperature control system and has the global adaptive overpower heating function. It can automatically call up idle power limit according to glass placement for on-demand superheat, improving transformer efficiency. It’s equipped with a new temperature control partition, which makes the optimized convective system structure more stable and the finished products much better.

Shanghai North Glass Automation Technology Co., Ltd. brought the glass automation connection loading NorthGlass’ new ERP and MES software system, with R&D, sales, production, engineering, after-sales and cloud data as an all-round one-stop service experience as the core. They cover the independent research and development of a storage scheduling system, cutting machine, automatic chip breaking machine, vertical chipping, vertical cleaning and a vertical edger to create a factory with an automatic information platform.

The coating production line independently designed and developed by NorthGlass utilizes multiple advanced technologies, which can process a maximum of 3.3 by 24 metres of ultra large glass. Modular design allows the process to be extremely flexible. Continuous cooperation with designers has enabled users to accumulate thousands of special film systems, including high-end double silver and triple silver glass products.

NorthGlass also brought their R450 semi-round tempered sandwich coloured glazed glass, S-shaped curved tempered insulating glass and light-stone unit wall. NorthGlass light-stone has luxurious decoration and a highly advantageous cost-effectiveness. It solves the pain point of industrialization of building exterior wall, and adds “new coat” for building as the “companion” of glass.