Founded in 1981, OMV Vismara is specialised in flat-glass processing technologies. Immediate and rapid growth has enabled the company to become an international known and appreciated manufacturer of flat glass processing machinery the world over.

|  |

OMV Vismara has been manufacturing special machines for drilling and milling for the flat glass sector for over 35 years. This focus on specialisation, a specific choice of the company’s owners, has enabled OMV to become an important reference name in a sector where large companies are its competitors, providing ‘tailor-made’ alternatives to potential customers who often look for machines designed for their needs.

HORIZONTAL AND VERTICAL MACHINES

OMV Vismara’s production range includes both horizontal and vertical machines, which can all be included in production lines of other machinery manufacturers, as robotic islands, or as stand-alone machines connected to a series of production lines.

Continuous R&D is fundamental in today’s market to be able to have the right products for glassmakers which, in turn provide the feedback needed, comparing logics and themes and, above all, the experience, knowledge and techniques of glass, coming from their customers.

The market often requires user-friendly machines and OMV is, in these cases, often not taken into consideration, as it is considered as a manufacturer of large complex and expensive machinery alone. In reality, company production has, over the years, expanded and now ranges from the solution for small- and medium-sized glassworks, up to large producers or production on an industrial scale.

This product specialisation gives OMV Vismara the possibility of designing individual orders according to customer requests, both in terms of space and specificity of processing.

DRILLING AND MILLING AS SPECIALISATION

OMV designs and manufactures drilling and milling machines for flat glass sectors: construction, doors, shower cubicles, furniture, earth moving machines, household appliances.

In recent years, the greatest demand comes from machines that make it possible to carry out drilling and milling (or cut-outs) in the glass, for the production of doors and shower cubicles.

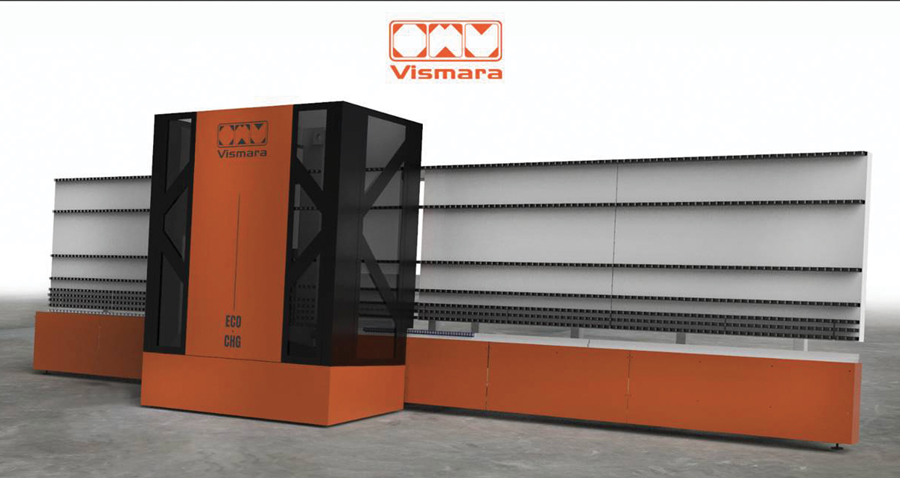

OMV’s product range for these demands includes lines made up of single machines, or single machines that carry out both types of processing (drilling and milling), as well as user-friendly machines and more performing machinery with tool storage (from 8+8 to 20+20 positions) and automatic tool changeover.

These more performing machines can take the place of the work centres used up to now, thus facilitating processes (for example eliminating the laborious task of equipping and positioning the suction cups).

A further important advantage is that of internal milling of mirrors, during which the position of the where the position of the vertical processing allows to avoid breakages during the movement that must be performed, when moving from horizontal to vertical position.

RESPONDING TO MARKET DEMANDS; COLLABORATION; NEW GENERATION

The demands of the market are increasingly technological and the watchword is automation as well as processing flexibility, for more frequent and continuous change of batches which requires flexible and easy-to-equip machines, also to allow to reduce costs of final products.

In addition to collaborating with other companies in the sector, OMV also has the possibility of supplying other types of machinery for grinding, handling, grinding and washing of flat glass thanks to a commercial partner company.

The new generation, which has been active in the company for some years now, has brought more energy and research into new and increasingly performing technical choices, which improve the tried and tested technology, simplifying processing methods and reducing timing.

POST-SALES AND ASSISTANCE

OMV has an immediate and efficient assistance service, guaranteed by qualified technicians who can intervene immediately ‘remotely’, thus eliminating on-site costs.

The company’s accurate, quick and effective after sales service is highly appreciated by customers, and thanks to prompt response to questions, eliminates production stops and, in turn, financial losses for customers.

Vismara OMV

www.omvvismara.com