For fire resistant glazing to deliver on its promise, it has to be tested as a complete system

Promat UK is supporting the fire resistant glazing market with a campaign to raise awareness of the significant risks of changing even the tiniest detail in the specification of building elements.

Despite the potentially catastrophic consequences of changing a specification for glazing, doors and windows which offer passive fire protection, specifications are still being routinely altered just to save a few pounds or due to a lack of technical understanding, according to leading fire, thermal and acoustic insulation manufacturer Promat UK.

Promat UK is supporting the market with a campaign to raise awareness of the significant risks of changing even the tiniest detail in the specification of building elements that are designed to protect lives and properties. At the heart of this is its ‘Specified for a Reason®’ message, which has now been registered as a trademark by Promat UK and serves as a reminder to everyone in the supply chain that the configuration of fire resistant glazing, partitions and doors simply must not be changed.

Ian Cowley, Regional Director (UK and Scandinavia) at Promat UK says: “For fire resistant glazing to deliver on its promise, it has to be tested as a complete system. All the elements and components are chosen to work together to achieve the level of fire resistance required. Change one element – such as the glass type or glazing beads – and there is absolutely no guarantee that the installation will offer protection above what you’d expect from standard glazing.

“Altering the specification on any aspect of a building’s design is nothing new, of course, and it is often very well-intentioned, but when lives are at stake it is too big a risk to take. If you change the specification of solar control glazing designed to prevent overheating, for example, the worst case scenario is that occupants may complain that their building is too warm in Summer months. Change a passive fire protection specification and it could mean the fire protection is as little as a few minutes, rather than the 30, 60 or 120 minutes it was intended to deliver – endangering life should the worst happen.”

Promat UK is working to ensure clients and specifiers can have total peace of mind when specifying fire resistant glazing. This includes practical guidance via an educational programme, including through its RIBA-approved CPD seminar, along with technical support at the earliest design stage. It also has numerous QA processes and checks in place to ensure that products are manufactured to a consistently high standard under the requirements of ISO 9001 and ISO 14001 (both 2015).

Ian continues: “It’s imperative for clients to have confidence in the full supply chain from product design and manufacture, through to post-installation checks. This is the ethos that lies behind our 360 degree ‘wheel of assurance’ and is the basis for our Promat SYSTEMGLAS® range.”

Promat SYSTEMGLAS® is a complete butt-jointed, fire resistant glazing package available in four versions depending on the chosen framing material. SYSTEMGLAS® Ferro is a steel frame system, SYSTEMGAS® Ligna provides a timber solution, and SYSTEMGLAS® Celare and Advenerat utilise PROMATECT H® which enables the frame to be concealed or painted/over-clad. The system is supplied directly by Promat UK for maximum traceability, and installation is completed exclusively by a network of approved installers to provide specifiers and clients with a Certificate of Conformity upon completion.

Visit www.promat-glass.co.uk to find out how access Promat UK’s specialist technical support or to learn more about Promat SYSTEMGLAS®.

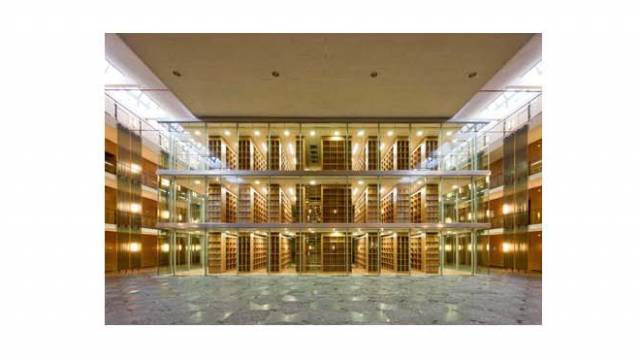

Internal glazing created using Promat SYSTEMGLAS, the system which offers complete supply and installation traceability for fire resistant glazing.