In a period when trade events have been put on hold, companies of all industrial sectors are working to find ways to continue their activities. In this article R.C.N. Solutions shows us how it is doing this, responding to demands for customisation and complete production solutions.

|  |

We are approaching the end of the year and it is a real challenge to accept that glasstec 2020 will not take place in its usual format, leaving a business gap that we hope will be filled by next year’s edition. In fact, the ongoing health emergency does not allow the regular operations of exhibitions and trade shows, and we are all responsible for virus containment measures, practising social distancing too.

R.C.N. Solutions is facing these global events in a world that seems to be moving in slow motion, and is responding to this dramatic time carrying out its job as usual, with customers and market as its priorities.

INVESTMENTS AND PROJECTS

The Covid pandemic has led to worries and perplexities regarding the future, and most investments and projects have been cancelled or postponed. In spite of this situation, R.C.N. has continued to receive enquiries for machines, especially concerning customisation and complete production solutions, which the company never neglects or underestimates because they are an important part of development.

But what has R.C.N. done this year, forced to work in closed premises?

First of all, it has enforced Internet technology to keep in contact with the global business world, especially to support the company’s technical service, penalised by the travel ban. R.C.N.’s way of fighting these restrictions has been to provide remote assistance to customers.

Company staff has worked hard to implement the new communication programme started in 2019; the new company logo was launched this year; while the new catalogue and website will be presented in a few weeks.

Furthermore, company growth also combines with the changed image of the advertising campaigns, focused more on concrete complete production proposals rather than around single products, and increasing the company’s presence in the major international trade magazines with articles and online news.

RESPONDING TO THE DEMAND FOR SAFETY GLASS PROCESSING MACHINES

One of the most important parts of R.C.N.’s business is the demand for safety glass, pushing the market for new products and equipment, increasingly responding to high quality standards.

Flexibility, is, in fact, the ability to be open to new, different requirements, that makes R.C.N. one of the most appreciated manufacturers of machines for the glass industry. The company started putting this policy into practice some years ago, after understanding that it was significant and highly important to have other choices in addition to the different standard sizes, offering more possibility for customisation in order to cover needs and demand and satisfy clients.

NEW SYSTEM FOR SAFETY GLASS

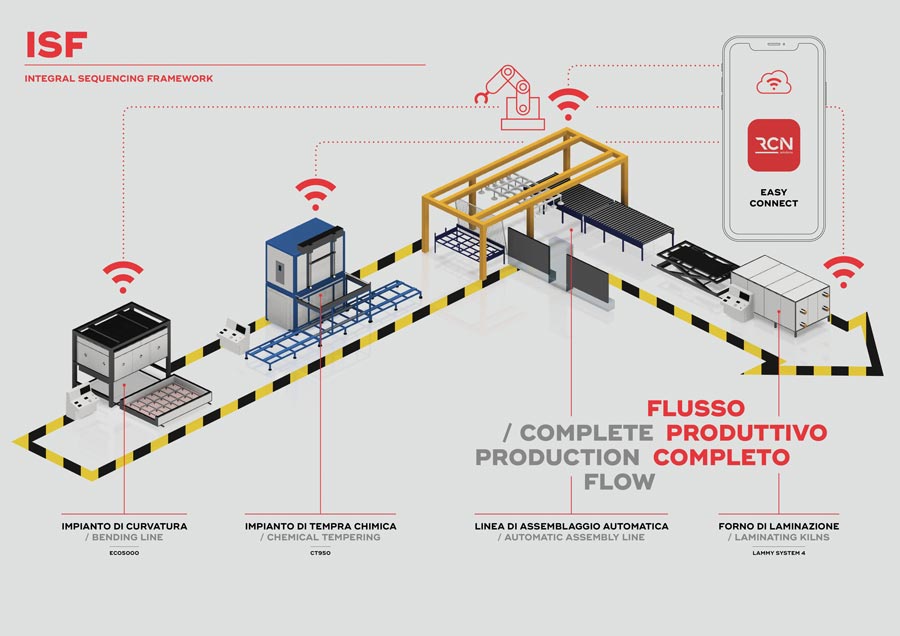

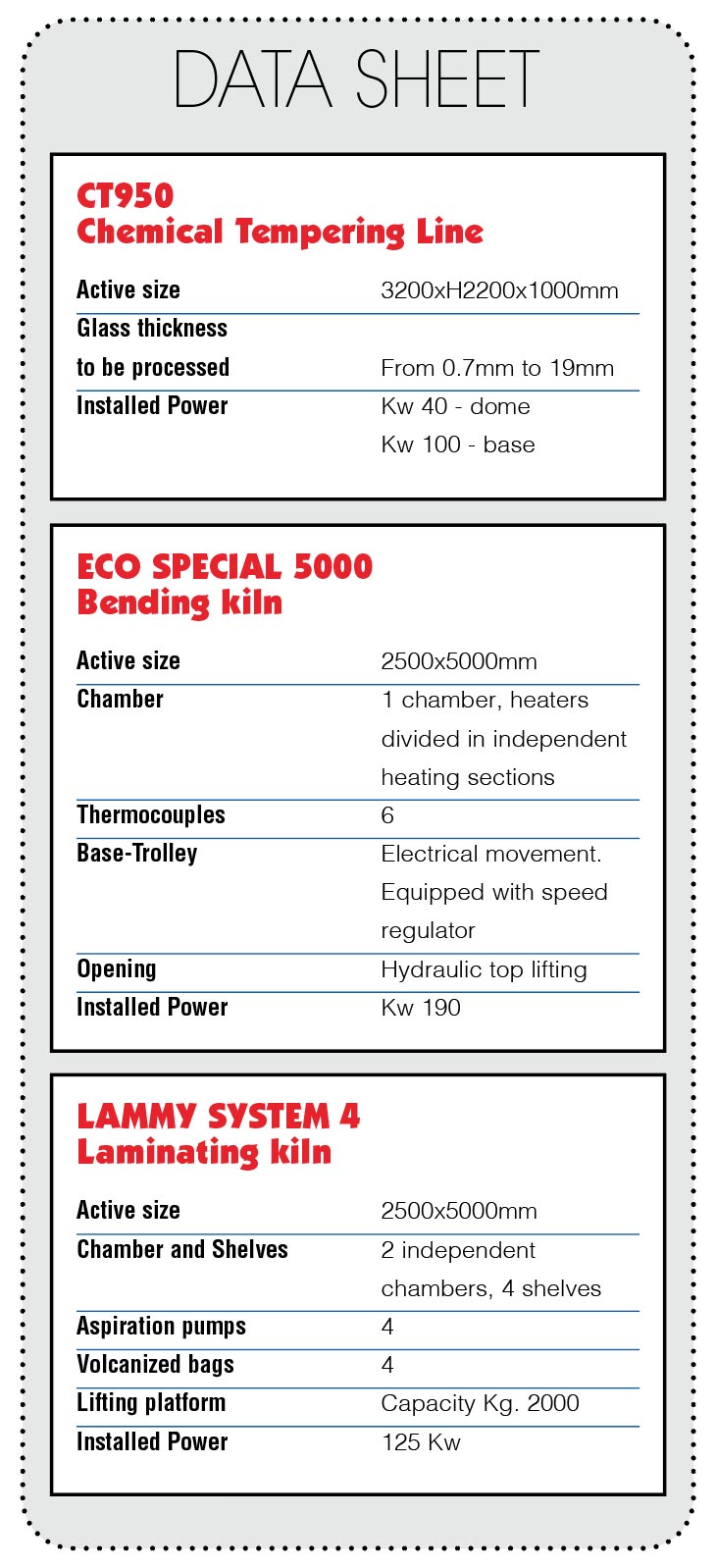

R.C.N. has always followed developments regarding the new use of glass, responding with a production layout made up of three essential plants: bending, chemical tempering and lamination. This trio responds to the production of safety glass, and curved glass in particular. The brand name of this system is ISF ‘Integrated Sequencing Framework’.

This production setting is very important because each line, which can be installed independently from the others, has several options: from the different independent heating zones of the bending kiln, controlled by PLC, for complex curves; to chemical tempering serving the optical, aeronautics automotive industries, etc.; right up to lamination, concluding the cycle for the production of safety glass.

The present trend is to use thin glass – almost like paper – for further lightweighting and transparency in buildings. Chemically tempered thin glass can be bent cold and at environmental temperature. It is then used for façades, after being laminated, as it is flexible and safe. This technique has created a lot of curiosity and interest especially because it revealed to be low energy and costs saving process.

LAMINATED GLASS WITH FINISHED EDGES

R.C.N.’s most recent revolutionary development is the new system to produce laminated glass with finished edges, during which the laminated glass comes out of the heating chamber without excess EVA on the edges, which is very difficult to remove and thus requires additional time and work.

The system is not based on complicated modifications of laminating recipes or the interruption of the intake at a certain stage, forcing clients to a daily revision of the production to adapt each type of glass thickness to the system, thus compromising the visual results with bubbles and quality adhesion result in the long terms.

R.C.N.’s system is, in fact, based on structured and integrated technology installed in the laminating kilns. This allows clients to have a real important option for both final products and costs, also saving time.

PRODUCTION STRONG POINTS RESPONDING TO CLIENT AND MARKET NEEDS

These results are a further example of R.C.N.’s skill in adapting its production to the needs and demands of its clients, and, of course, its constant efforts. The sequence of all these elements create the company’s special DNA, which will continue to be an important part of the company in its future growth.

R.C.N.’s production has a number of strong points that create added value, together with the possibility to check processes remotely, using the new R.C.N. ‘Easy Connect’ App. Quality control is an important, delicate job, and machine monitoring is part of this procedure. R.C.N.’s App allows remote control from PLC, tablet and/or mobile phone, also giving the chance to modify production parameters during processing. The same App can be used to start a late run or to check remotely together with the R.C.N. staff.

R.C.N. has, as we can see, used this difficult time as the motivation to consider new perspectives cultivating remote contacts and work, while keeping an eye on market requirements and clients’ demands, and – of course – being ready for new goals.

RCN Solutions Srl

www.rcnsolutions.it