About Rákosy Glass

Rákosy Glass Kft. was founded in 2007 as the successor to Rákosy Üvegipari Egyéni Cég and 156 people are currently employed by the company. The majority of sales take place on the Hungarian market – primarily products for complex projects in the architectural or decorative glass sector are also exported, whereby Rákosy Glass is able to impress with its expertise and specialised solutions and technologies.

The company is constantly expanding its product portfolio and range of services. In doing so, Rákosy consistently demonstrates speed and flexibility. The focus of the company’s activities always lies on individual glass solutions and surfaces that make space for light and therefore elevate the quality of the visual environment. Their broad product portfolio ranges from special heat-insulating glass in extra-large dimensions, individual doors and windows, motor-driven sliding doors, all the way up to heating glass.

The company is constantly expanding its product portfolio and range of services. In doing so, Rákosy consistently demonstrates speed and flexibility. The focus of the company’s activities always lies on individual glass solutions and surfaces that make space for light and therefore elevate the quality of the visual environment. Their broad product portfolio ranges from special heat-insulating glass in extra-large dimensions, individual doors and windows, motor-driven sliding doors, all the way up to heating glass.

A designated showroom in the production area presents the innovative solutions of the family-run business; from special textured glass sheets to oversized glass sheets for sliding glass doors, and the latest innovation from the house of Rákosy, the glass heating system.

A designated showroom in the production area presents the innovative solutions of the family-run business; from special textured glass sheets to oversized glass sheets for sliding glass doors, and the latest innovation from the house of Rákosy, the glass heating system.

The SKC Glass Heating System from Rákosy

With this invention, the Hungarian glass processor is meeting the new requirements of modern living space design, which is increasingly demanding a more aesthetic, brighter or light-flooded ambience. On this basis, the in-house R&D team developed a state-of-the-art glass innovation, glass heating – an entirely new heating system.

With this invention, the Hungarian glass processor is meeting the new requirements of modern living space design, which is increasingly demanding a more aesthetic, brighter or light-flooded ambience. On this basis, the in-house R&D team developed a state-of-the-art glass innovation, glass heating – an entirely new heating system.

The design consists of two tempered safety glass sheets. Here the inner glass is laminated with a heating coating and can therefore satisfy all safety requirements, even in the event of glass breakage. With low costs, this system delivers dependable temperatures and is an excellent alternative to conventional heating systems. “We are proud that we are able to offer our customers such solutions, thereby offering not only savings on heating costs but also alternative options for interior design. Such innovations will certainly become more and more important in the future,” said Mr. Rákosy.

Rákosy‘s LiSEC cutting system

Mr Rákosy acquired the first LiSEC cutting table as a second-hand model in 1998. At that time, the cutting table had already been in use for 5 years. It was only after 21 years in service that this first LiSEC purchase was replaced with a new LiSEC cutting table last year.

“The investment really paid off,” Rákosy explained. “First of all, the technology used was well ahead of its time back then and was therefore always used to our satisfaction over the subsequent years. And secondly, LiSEC machines are a prime example of reliability.”

In the meantime, the bright and well-organised production hall of the Hungarian glass processor has been home to a LiSEC cutting system consisting of seven machines – including two LiSEC GFB60/30RE-S (2008 and 2019 glass cutting tables for float glass), a VB60 laminated glass cutting bridge from 2019, two LiSEC BTS (2008 and 2019 breakout tables), a LiSEC PKL (2008 gantry loading system) and a LiSEC ATL (2008 movable glass loading station).

In the meantime, the bright and well-organised production hall of the Hungarian glass processor has been home to a LiSEC cutting system consisting of seven machines – including two LiSEC GFB60/30RE-S (2008 and 2019 glass cutting tables for float glass), a VB60 laminated glass cutting bridge from 2019, two LiSEC BTS (2008 and 2019 breakout tables), a LiSEC PKL (2008 gantry loading system) and a LiSEC ATL (2008 movable glass loading station).

The fully automatic glass cutting table is equipped with an additional grinding device, which enables the removal of coatings. Shapes and digitised shapes can be cut without difficulty. Further advantages of the LiSEC table are a second oil feed, automatic cutting pressure control and fixed stripping brushes.

The LiSEC PKL is a self-propelled glass loading station with a rotating suction frame. Thanks to the rotating double suction frame, the glass gantry loading system is able to stack large format sheets automatically and precisely. This is made possible by automatic synchronisation, which is controlled via optical sensor technology. Rákosy Glass has 60 loading positions and cycle times are shorter due to travel path optimisation. The laser measuring system is maintenance-free and wear-free and can also be designed as a half gantry or bridge.

The LiSEC ATL is a stationary or movable glass loading station, which can be loaded by means of an automatic gantry loading system and is used for feeding a downstream cutting system. When the table surface of the ATL is in vertical position the LiSEC gantry loading system places the glass sheet to be processed on the ATL. The table surface is then brought into a horizontal position. This is followed by glass sheet outfeed to the downstream glass cutting system. The key advantages are the simple and robust design, as well as the input speed of up to 60 metres per min. The LiSEC ATL is also extremely low-maintenance due to the use of a hydraulic tilting device.

Cooperation with LiSEC

Mr Rákosy is extremely satisfied with his cooperation with LiSEC, in particular with regards to service and spare parts availability. “We had no real problems with the LiSEC team – on the contrary, the discussions were always highly constructive and goal-oriented. If something doesn’t work at our site, the LiSEC team always does its best to find a quick solution – although such situations are infrequent. Our LiSEC cutting system has never stood still longer than one day.” In such cases, original LiSEC spare parts are used, which have the advantage of rapid availability and perfect fitting accuracy.

Mr Rákosy is extremely satisfied with his cooperation with LiSEC, in particular with regards to service and spare parts availability. “We had no real problems with the LiSEC team – on the contrary, the discussions were always highly constructive and goal-oriented. If something doesn’t work at our site, the LiSEC team always does its best to find a quick solution – although such situations are infrequent. Our LiSEC cutting system has never stood still longer than one day.” In such cases, original LiSEC spare parts are used, which have the advantage of rapid availability and perfect fitting accuracy.

LiSEC machines guarantee high product quality for the end consumer, and for years to come. For Mr Rákosy, this is one of the main arguments in favour of a LiSEC cutting system. “The precision is consistent and the performance of the machines is constant over the years – which increases our production reliability immensely.”

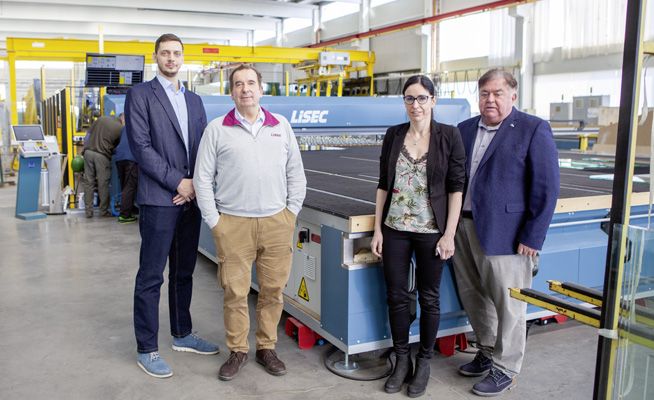

However, the cooperation with the Hungarian LiSEC team is also outstanding: LiSEC agent Fábián Kristóf and LiSEC engineer Regenyei Béla are always welcome at Rákosy Glass and together with Austrian colleagues successfully solve all Customer’s demands.