RATH offers the global glass industry premium refractories for the entire glass manufacturing process, and places a strong focus on saving CO2 and energy.

See for yourself at glasstec 2024

The international refractories manufacturer will be at glasstec in Düsseldorf from October 22 to 25 to present its future-proof refractory solutions: from solutions for the regenerator and the melting end to the new, advanced FOURATH®4 feeder expendables series, newly developed channel blocks and innovative ceramic hot gas filter elements.

The glass industry can rely on RATH’s future-proof refractory solutions and expertise in providing heating and melting solutions from a single source. RATH products are manufactured worldwide in state-of-the-art production facilities and on the basis of the latest application know-how.

RATH always takes sustainability into account

With its innovative refractory solutions, RATH also supports the glass industry in its ambitious efforts to reduce its carbon footprint and save energy.

Checker bricks, chrome-alumina overcoating blocks and melter burner blocks

At glasstec, RATH will be showcasing solutions for the regenerator and the melting end, such as checker bricks, pressed 1000x500x200 bottom blocks, chrome-alumina overcoating blocks, melter burner blocks and more.

At glasstec, RATH will be showcasing solutions for the regenerator and the melting end, such as checker bricks, pressed 1000x500x200 bottom blocks, chrome-alumina overcoating blocks, melter burner blocks and more.

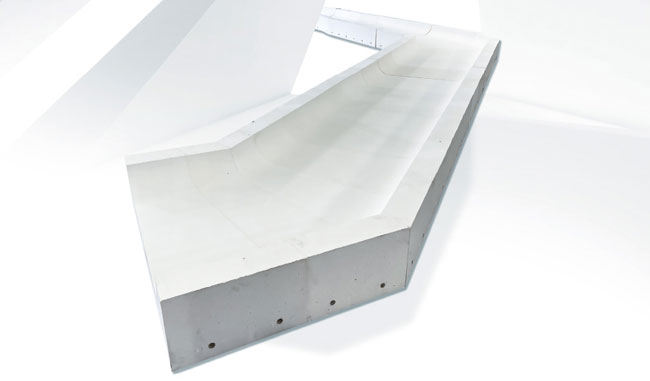

Smoothest surface for the best material flow

Speaking of forehearths: The newly developed FOURATH® 420 zircon-mullite and Vibrorath K99 high-alumina channel blocks, which are made of premium materials and manufactured using the most precise technology, will be on show at glasstec.

Longer service life with the new, advanced FOURATH®4 feeder expendables series

Also to be found at the RATH booth: the new, advanced FOURATH®4 feeder expendables series, which includes spouts, spout covers, tubes, orifice rings and plungers. FOURATH®4 technology, based on an optimized formulation that has been exclusively developed and produced by RATH, enables a longer service life, better glass quality and reduced costs.

Also to be found at the RATH booth: the new, advanced FOURATH®4 feeder expendables series, which includes spouts, spout covers, tubes, orifice rings and plungers. FOURATH®4 technology, based on an optimized formulation that has been exclusively developed and produced by RATH, enables a longer service life, better glass quality and reduced costs.

Hot gas filtration: RATH helps to meet emission requirements in industrial plants

Hot gas filtration is becoming increasingly important when it comes to reducing exhaust gas emissions. At glasstec, RATH will be presenting its innovative ceramic hot gas filter elements. For many years, the company has been developing innovative ceramic hot gas filter elements that make it possible to filter particle-laden industrial flue gases at temperatures of up to 1,000 degrees Celsius and to reduce emissions of nitrogen and sulphur oxides, as well as fine particulates. RATH ceramic hot gas filters are produced in Europe using RATH fibres and available in lengths from 1 to 6 metres.

Hot gas filtration is becoming increasingly important when it comes to reducing exhaust gas emissions. At glasstec, RATH will be presenting its innovative ceramic hot gas filter elements. For many years, the company has been developing innovative ceramic hot gas filter elements that make it possible to filter particle-laden industrial flue gases at temperatures of up to 1,000 degrees Celsius and to reduce emissions of nitrogen and sulphur oxides, as well as fine particulates. RATH ceramic hot gas filters are produced in Europe using RATH fibres and available in lengths from 1 to 6 metres.

Manfred Salinger, Head of Advanced Ceramic Filtration Solutions RATH Group, and a proven expert on hot gas filtration, will share his extensive knowledge on the topic in an expert lecture at glasstec on October 23 from 14:10 to 14:30 in Hall 10.