Revimac is now introducing a new family of equipment that many in the business might find useful, the Revimac NTR cullet conveyor.

Revimac cullet conveyors are designed to work dry (not suitable for glass drainage), are all featuring hot galvanized steel structures, stainless steel conveyor belts and are divided into 2 main families:

- Revimac NTR Single-Shop: medium load capacity: width ~ 300 mm

Application: Hot-end line evacuation;

Installation: in front of the annealing lehr between cross conveyor and stacker;

Operation: continuous or intermittent (sensor activated). - Revimac NTR Multi-Shop: high load capacity (elevator): width ~ 580 mm

Application: evacuation from cellar (can displace the cullet from the whole furnace, up to 360 TPD);

Installation: in the cellar for transportation to higher levels;

Feature: Combination of horizontal and inclined conveyors;

Operation: continuous or intermittent.

Revimac NTR single shop

The Revimac NTR single shop conveyors are designed to remove the hot glass cullet falling from the cross-conveyor and to convey it to the basement through the openings in the shop floor.

Flat conveyor for the transport of glass cullet with metal “shutters belt” conveyor chain. The conveyor operates intermittently in only one direction.

The belt is made of stainless steel plates connected to each other by connecting pins and driven by a chain.

The equipment supply includes : control panel, metal structure with ground supports, motorization, chain transmission with drive and idle sprockets, shutter transport system, side containment panel, end hopper and rope activated safety system.

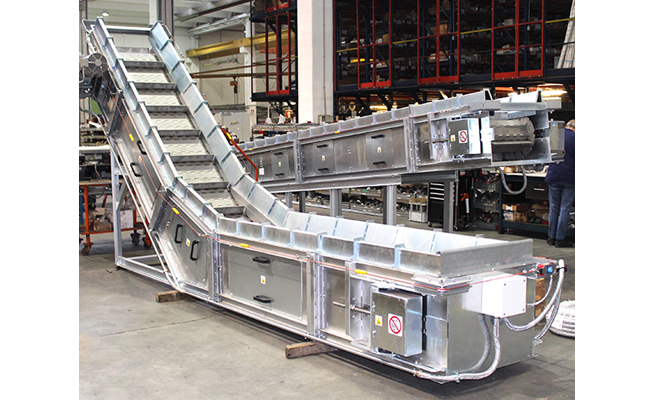

Revimac NTR multi shop

Revimac NTR multi-shop conveyors are designed for transporting glass cullet from the extinguisher, or from single-shop conveyors that evacuate the front of the annealing lehrs.

The NTR is placed in line with other scrapers used for removing cullet from the production lines and for conveying it to further belts to carry the cullet to upper floors.

The conveyor-elevator can have an horizontal or inclined section up to 45°approximately, it is designed for continuous or intermittent operation and may also be installed outside of the building.

The conveyor is made of one hot-galvanized steel frame housing a stainless-steel shutter belt driven by an electric gear-motor.

A rope activated safety system interrupts operation if engaged by the operator.

Each Revimac NTR scraper system, single-shop and multi-shop, is tailor-made and designed depending on the layout, the structure of the buildings and on the installation and functional requirements.

Each Revimac NTR scraper system, single-shop and multi-shop, is tailor-made and designed depending on the layout, the structure of the buildings and on the installation and functional requirements.

Auxiliary systems, such as cameras, can also be integrated into the control system to monitor the cellar.

For more information please contact Revimac.