Revimac has been a dynamic presence in the hollow glass world for more than thirty years with two separate souls. On one side, Revimac can perform professional IS machine re-manufacturing and on the other side it is one of the very few companies capable to deliver a complete ware handling equipment range including ware transfers, cross conveyors and stackers.

It’s also noticeable the continuous upgrade to which Revimac’s machines are subjected.

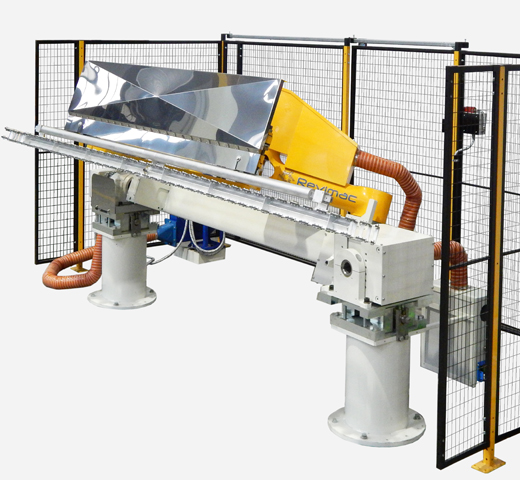

Revimac in the past was able to design and develop the world-wide recognized top performer, the RSS-100 Servo Stacker.

This three axis RSS-100 Servo Stacker is definitely Revimac’s finest and Revimac has just released a recent update consisting in new gearbox and servo motors to suit a major upgrade on the software interface, which is now adopting the same philosophy behind the recent 5 axis stackers family. This update is now granting a speed up to 22 lehr loading cycles per minutes.

This three axis RSS-100 Servo Stacker is definitely Revimac’s finest and Revimac has just released a recent update consisting in new gearbox and servo motors to suit a major upgrade on the software interface, which is now adopting the same philosophy behind the recent 5 axis stackers family. This update is now granting a speed up to 22 lehr loading cycles per minutes.

Then, if the RSS-100 is outstanding in terms of performance, there is another Stacker from Revimac, that is definitely worth mentioning.

The RSS-950 5-axes servo-stackers is Revimac’s most gentle and precise stacker thanks to its servo controlled steady bar that allows the so-called “GRAB MODE”.

Through the “grab mode” function the stacker is able to gently pick-up the containers between push-bar and steady-bar by the neck or by the body and lift them for direct unloading onto the annealing lehr belt; this function is recommended for highly unstable containers.

The Steady-bar Unit is fully programmable to handle unstable glassware and featuring two independent servo-motors for the accurate and repeatable positioning of the steady-bar, both for the linear (forward-backward) and the vertical (up-down) adjustment.

Self learning control system

Self learning control system

To increase the usability of such a performing machine, both the RSS-100 and the RSS-950 control systems are based on the same software philosophy, which is also working with some “auto learning” functions.

This software, developed by Revimac enables the stacker to manage automatically the loading profile with few inputs and to phase the loading curve by detecting the speed of the IS machine.

The control cabinet (to be placed inside one air-conditioned control room) contains the Motion Controller that is connected to an industrial PC which functions as HMI (touch screen 15”).

The main characteristics of the operator interface are:

- Preview loading curve simulation

- Simplified management of the loading curve by setting 4 commands only (approach speed, pushing speed, start position and end position)

Revimac delivered all around the world 495 ware transfers, (available in 3 model for different speed rate) 580 stackers (239 servo stackers), 547 cross conveyors and all of these ware handling equipment have been installed to serve the output of many different machines of different producer and in several configurations.

The RSS-100 is the stacker to have for high speed lines, for example it easily works with 12 section quad gob (672 bpm) or also on a tandem 8+8 section triple gob (720 bpm).

The RSS-950 have been a big game changer for perfumery and cosmetic container’s producer that are handling instable and small items as for example perfume bottle cap or very small pharmaceutical container.

That’s an indication in how Revimac, thanks to the collaboration with its customers, the competence of its team and the experience collected in its thirty years in the field is not only able to offer spot-on solution for the actual needs of the market, but it’s also the most consistent partner for tomorrow’s request.

Revimac is looking with confidence to the most demanding performance in the hollow glass industry to push over and over to improve performance and reliability of its equipment to grant customers always the ultimate design.