The main job of transfer wheels is to move the containers from the machine conveyor to the cross conveyor, but one of the crucial jobs is also to properly space containers and to put them in the right orientation to prepare a perfect lehr loading and it’s very important to not underestimate those aspects because a good transfer wheel could lead to major benefit along the whole line.

Revimac during the years have been focusing its products range on some common characteristics, such as:

- Chain guide is integrated in the front side of the steel plate, while in the back side is positioned the chain tensioner;

- Drive sprocket is equipped with a safety clutch;

- Base frame also integrating support mechanism that allows easy positioning of transfer head with orthogonal adjustment for accurate regulation;

- Quick change fingers easily accessible through the cover opening for an easy spacing setup.

Those few features are the base for reliable and easy to operate machines and with this in mind, Revimac developed different transfer-wheel models to suit most lines.

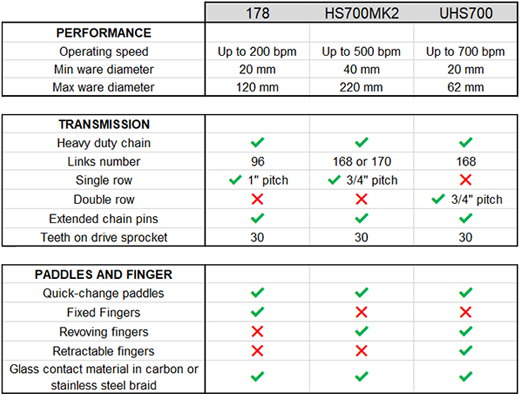

The first model is the all-purpose wheel, the HS700 MK2 (high speed 700, second generation profile). This wheel can handle up to 500 bpm offering wide possibilities for adjustment and customisation.

Revimac HS 700 MK2 is designed with an optimized transfer angle to assure quick and stable handling of the glassware, supported with ware guide plates positioned on the bottom and upper part of the structure.

The other peculiar feature is the improved quick-change fingers with swing (or revolving) retraction. The alloy steel base frame also integrates a support mechanism that allows easy positioning of transfer head with vertical and lateral adjustment for accurate ware handling.

Drive sprocket equipped with pneumatic torque limiter (with electric contact signal for emergency) to prevent damage in case of jamming due to accidental interference.

For the most demanding lines Revimac developed another model: the UHS700. This model can transfer with ease up to 700 bpm.

For the most demanding lines Revimac developed another model: the UHS700. This model can transfer with ease up to 700 bpm.

The distinctive feature of this device is the design of its retractile fingers which doesn’t swing (as in the HS700 MK2) but, thanks to a dedicated cam, operate a linear retraction. Furthermore, the cam guide ensures a dampening effect that help stability at high speeds avoiding bounce or vibration. These features allow the UHS700 to precisely transfer glass container at 700 bpm.

Revimac still produce its evergreen model, the “Type 178” which offers simplicity and reliability at a great price point. Revimac 178 is fully interchangeable with other similar wheels in the market and it’s the perfect solution for lines up to 200 bpm.

The last transfer wheel is the Parallel wheel which is requested in some lines where the main conveyor is parallel to the cross conveyor.

Revimac, however, is not done. This is just a quick glimpse of their product range to suit the vast majority of the lines’ needs.

Revimac, however, is not done. This is just a quick glimpse of their product range to suit the vast majority of the lines’ needs.

During the years Revimac developed many customized solutions for their clients, such as for non-round containers, special spacing, or even for lines which speed is as quickly as 1000 bpm. Revimac has many solutions available and the company is always looking forward to the production needs of tomorrow.