STRATO® RIGIDO: application and end of use

Satinal‘s STRATO® RIGIDO is a structural interlayer of the STRATO® range. It guarantees exceptional hardness and resistance, thanks to certified characteristics according to standard EN 16613.

Satinal‘s STRATO® RIGIDO is a structural interlayer of the STRATO® range. It guarantees exceptional hardness and resistance, thanks to certified characteristics according to standard EN 16613.

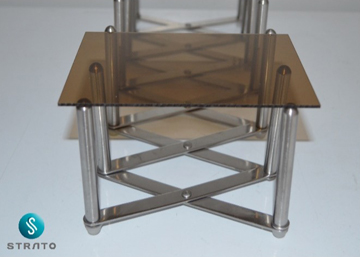

STRATO® RIGIDO is the ideal lamination solution for use in applications where security and durability come first. The high quality and hardness given by STRATO® RIGIDO allows for lamination of thinner glasses, contributing to sustainability and achieving better structural performances compared to standard laminated glasses. Therefore, it is possible to reduce the quantity and thickness of glasses used without compromising the security of buildings and the resistance of a STRATO® RIGIDO interlayer laminated glass.

Safety glasses, laminated with STRATO® RIGIDO, provide a higher level of protection against strong impacts. The laminated structure is not weakened even in cases of breakage of the glass component, thus preserving the stability and safety of the product.

Safety glasses, laminated with STRATO® RIGIDO, provide a higher level of protection against strong impacts. The laminated structure is not weakened even in cases of breakage of the glass component, thus preserving the stability and safety of the product.

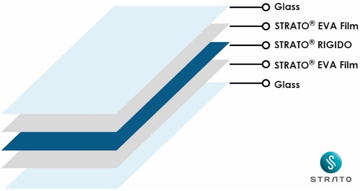

The application of STRATO® RIGIDO in the glass lamination process involves, first of all, the positioning of RIGIDO plate between two STRATO® EVA films and, eventually, the lamination of the glass.

The applications of STRATO® RIGIDO are among the most various and sometimes the most extreme: areas with high incidence of hurricanes, facades of buildings, parapets, etc.

Moreover, structural glass has recently found its use in the recovery or preservation of ancient buildings at risk of decay, with the creation of structural laminated glass roofs.

STRATO® RIGIDO: what is new

In order to meet the growing market’s demand, the product offer has been expanded according to specific criteria: aesthetics, areas of application and handling.

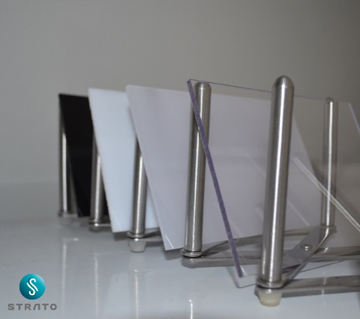

Colours: the most interesting innovation concerns the introduction of RIGIDO COLOUR. It is possible to access a wide range of colours, allowing for personalization of structural surfaces with modern and cutting-edge shades.

Colours: the most interesting innovation concerns the introduction of RIGIDO COLOUR. It is possible to access a wide range of colours, allowing for personalization of structural surfaces with modern and cutting-edge shades.

Dimensions: dimensions are important. That is why STRATO® RIGIDO is available in different formats, from a minimum width of 120 centimetres to a maximum width of 250 centimetres. Moreover, STRATO® RIGIDO is available in different thicknesses and roll lengths.

Packaging: STRATO® RIGIDO plates can also be packed in rolls, optimizing shipments.

Storage: STRATO® RIGIDO is not a hygroscopic material and therefore does not fear moisture. It is therefore not necessary to store it in expensive clean rooms with controlled temperature and humidity.

Satinal SpA has been the first EVA film production site in Italy, a reference point in Europe for the supply of 100 percent made in Italy interlayers. To this, it is added STRATO® RIGIDO, in a wide colour palette, different sizes and thicknesses, to respond to multiple purposes of use.

The application of STRATO® EVA film is a process requiring great precision for the applied temperatures and cycle times. The quality controls, which are carried out in Satinal’s R&D Lab, aim to guarantee perfect adhesion of the material to the glass surface. The deep experience acquired by Satinal in the treatment of EVA-based materials is essential to master its potential applications and fully exploit their characteristics.