To decrease GHG (greenhouse gas) emissions to combat climate change, Saverglass Group is working on multiple fronts to reduce its energy consumption: increasing the percentage of cullet in products, changing raw materials, optimizing product and packaging designs and replacing furnaces that run on fossil fuels with low-carbon models.

Measuring and identifying emissions to reduce them

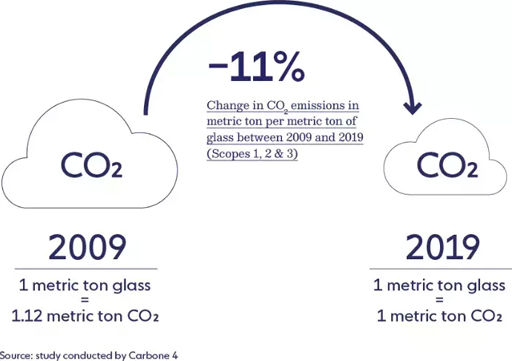

Before measuring progress, you have to know your starting point. This is why Saverglass conducted its first carbon footprint analysis in 2009 with the assistance of the consulting firm Carbone 4. The second assessment, conducted in 2019, again with Carbone 4, highlighted progress: the Group had reduced its GHG emissions by 11 percent over the space of 10 years.

This assessment also resulted in a detailed analysis of the sources of emissions. Saverglass’ carbon impact is due mainly to the energy consumed in the glass-melting process: furnaces must heat raw materials to a temperature of approximately 1,500 degrees Celsius (2,700 degrees Fahrenheit) to melt them. This knowledge formed the basis of a road map to gradually decarbonize operations across the entire value chain.

Saverglass Group road map: taking action along the entire value chain

This road map, drawn up with the assistance of Carbone 4, should enable the Group to gradually reduce CO2 emissions in both upstream and downstream operations. The strategy is to prioritize reducing emissions from the manufacturing process while also working on induced, direct (Scopes 1 and 2), and indirect (Scope 3) emissions, recognizing that the latter accounts for 40 percent of the Group emissions.

The objectives are ambitious: reduce the emissions of the manufacturing processes by 45 percent before 2035 and by 36 percent across the entire value chain (Scopes 1, 2, and 3). Looking towards 2050, Saverglass wants to continue its efforts and encourage innovations with the goal of getting on track with the 2 degrees Celsius reduction trajectory. For Saverglass, this means achieving carbon neutrality by 2050.

Action plans

The main pathways for improvement are a continuation of the actions Saverglass Group has already embarked on:

- Improving energy efficiency

- Boosting the share of clean energy in the energy mix used to manufacture glass.

A concrete, detailed action plan has been drawn up for each site, and the carbon impact of each solution proposed in the plan has been measured. The aim is to identify the levers for improvement that employ reliable, affordable technologies.