Over 30 years of working with passion to provide high quality machinery, and continuous investments in new technologies and research. This is how Schiavo offers the best solutions, and sturdy and reliable machines. In this article, the company presents its vertical drilling/milling machine – the Schiavo FV1000 – designed especially for small/medium glassworks.

|  |

How can a small/medium glassworks be independent for glass drilling and milling? These processes normally require a CNC work centre. But CNC machines are expensive for small/medium glassworks, and return on investment time is usually quite long.

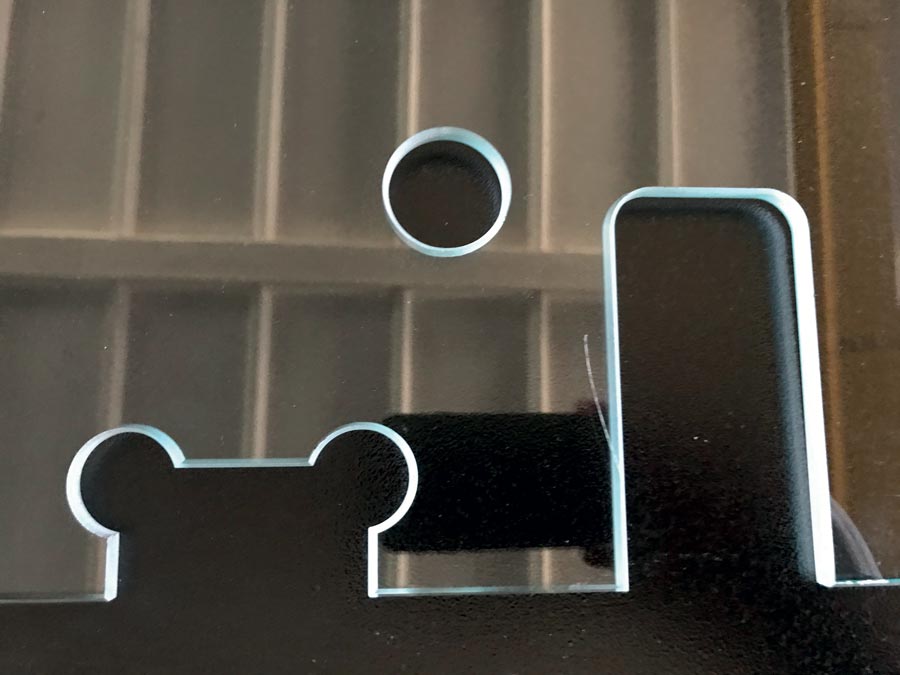

So what can be done? Is there a solution that costs a third of these systems? The answer comes from an Italian manufacturer with over 30 years of experience in high quality glass machines – Schiavo – with the Schiavo FV1000, which allows any size of glassworks to perform all type of carving, holes and shapes required for the installation of hinges, locks and accessories on glass doors and glass for furniture. Other possibilities include squares, circles, rounded corners, corner cut-outs, mickey mouse silhouettes, ‘U’ shapes and much more.

THE FV SERIES

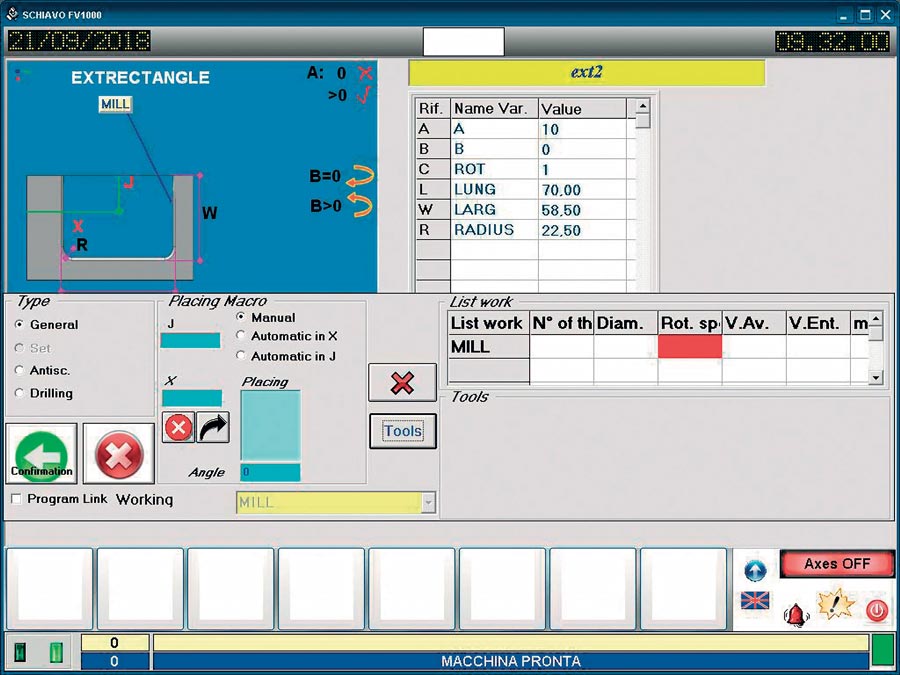

The possibilities are almost endless with the FV series, thanks to its rich built-in shape library, where all shapes can be edited and saved as new. Additionally, ISO or DXF files can be imported into the machine from any computer via LAN or Wi-Fi, or via the USB port with a pen drive. The ‘direct drawing’ procedure uses internally stored shapes that can be easily modified by the operator by entering the relative parameters. This operating mode is extremely simple and rapid and can be carried out by operators who are not specifically trained or experienced.

The positioning of the glass pane is carried out manually by the operator with a motorized reference stop controlled by the CNC module integrated in the machine.

In the basic version the operator only has to slide the glass until it touches the motorized reference stop. Then by pressing a pedal the machine blocks the glass plate and starts the drilling/milling process.

As an option, the FV1000 is equipped with a pneumatic gripper for automatic positioning of the glass. With this version the operator only has to deal with the loading and unloading of the glass. All other operations are handled automatically by the machine making the process much faster.

So why invest in a vertical work centre when the FV1000 is able to satisfy 90 per cent of the operations that are generally performed by these work centres?

The FV1000 is also equipped with software for remote assistance and classified as Industry 4.0.

OTHER MACHINES AND PRODUCTS

The range of machines offered by Schiavo – all manufactured in Italy, guaranteeing ease of use and reliability – use high quality components to ensure long-lasting working life and energy-efficiency.

Schiavo also provides complete solutions consisting of vertical washing machines in line with vertical drills and milling machines, which can be connected together to synchronize the speed and thickness of the glass.

Schiavo Srl

www.schiavotech.it