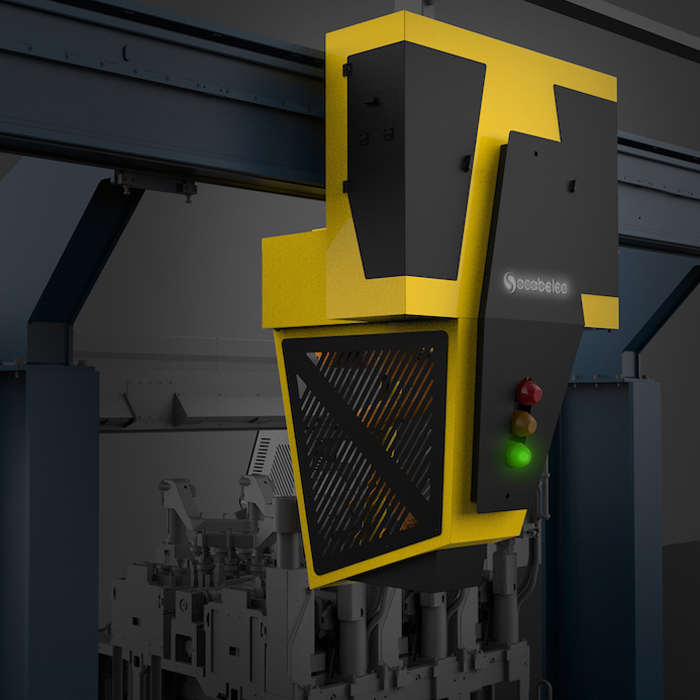

In the competitive world of glass container manufacturing, efficiency, safety and quality are critical to success. Socabelec, a leader in robotic automation for the glass container production industry, is proud to introduce the RomoSwab—a cutting-edge robot designed to automate the mould lubrication process on the blow side of IS machines.

This game-changing solution, launched in October 2024, tackles long-standing issues with manual swabbing and delivers unprecedented levels of productivity and safety to glass manufacturing operations.

Furthermore, the RomoSwab supports the industry’s drive toward sustainability, reducing waste and optimizing resource use.

Solving the challenges of glass container production

For years, glass container manufacturers have relied on manual lubrication methods that expose workers to safety risks, cause frequent production stoppages and lead to inconsistencies in product quality.

For years, glass container manufacturers have relied on manual lubrication methods that expose workers to safety risks, cause frequent production stoppages and lead to inconsistencies in product quality.

These challenges are particularly prevalent in the high-demand sectors of glass container production for cosmetics, pharmaceuticals, beverages and eco-friendly glass containers.

The RomoSwab completely automates the lubrication process, eliminating the need for manual intervention and enabling manufacturers to increase production efficiency while improving worker safety.

This innovative solution ensures uniform lubricant application to moulds, which reduces product defects, boosts quality and contributes to a more environmentally responsible manufacturing process.

How does RomoSwab work

The RomoSwab is engineered to fit seamlessly into existing IS machines used in glass container manufacturing.

It leverages the advanced capabilities of the FANUC LR Mate robot, offering precise, repeatable lubrication with a positioning accuracy of ±0.02 mm. This precision ensures that every mould receives the exact amount of lubricant required for optimal performance, leading to a consistent product output and minimizing waste, which aligns with the industry’s goals for sustainable production.

Technical specifications

Operating voltage: AC 3*400 V ± 10 percent

Minimum pressure: 6 bar

Tension: 200-240 V AC

Thanks to its plug-and-play design, the RomoSwab integrates effortlessly into current glass container production lines, minimizing downtime during implementation. This compatibility makes it a highly attractive option for glass container manufacturers looking to modernize their operations while also reducing their environmental footprint.