The latest evaluation by ift Rosenheim confirms that Sparklike’s Laser Portable 2.2™ meets the accuracy requirements of EN 1279-3 for measuring gas concentrations in insulating glass units (IGUs). With its tunable diode laser absorption spectroscopy (TDLAS) technology, the device provides non-invasive, precise measurements across various configurations of double and triple glazing.

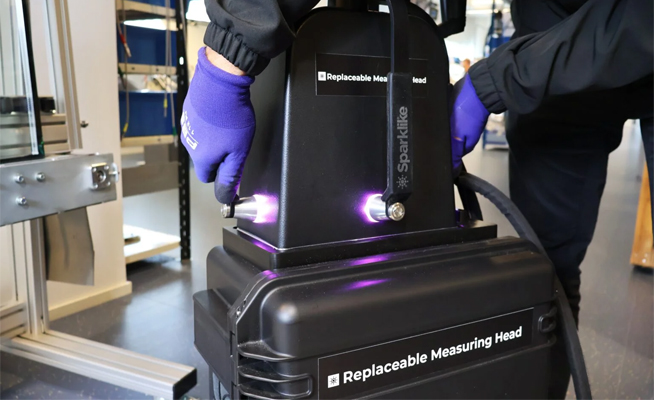

The Sparklike Laser Portable 2.2 is based on TDLAS technology, which uses a vertical-cavity surface-emitting laser (VCSEL) to measure oxygen levels and calculate argon or krypton concentrations. This approach allows for measurements through coatings and laminated glass without damaging the IGU or requiring additional components inside.

Key features of the device

- Scanning of IGU dimensions to ensure precise measurement points.

- Measurement through uncoated, coated and laminated glass.

- Application in both double- and triple-glazed units.

This versatility makes the Sparklike Laser Portable 2.2 a valuable tool for quality control in the production of insulating glass.

Testing and Key Findings

The device underwent detailed testing at ift Rosenheim, which included:

- Gas Concentration Measurement in Double and Triple Glazing

- Measurements from both sides of IGUs.

- Assessment through various coatings and glass thicknesses.

- Testing with freshly filled argon gas samples at 92.5 percent concentration.

- Analysis of laminated glass with multiple PVB layers.

The results demonstrated high precision and compliance with industry standards:

Double-Glazed Units

- Average deviation of 0.6 percent from reference gas chromatography (GC) measurements.

- No significant effect from uncoated or laminated glass.

- Minimal influence from low-emissivity coatings, within the permissible range.

Triple-Glazed Units

- Average deviation of 1 percent from GC measurements for combined cavity results.

- Accurate performance even with laminated glass and asymmetrical thicknesses.

- Slight influence of coatings, with deviations within EN 1279-3 requirements.