In 2020 Stoelzle joined forces with the German association International Partners in Glass Research, aimed to increase and maintain the competitiveness of glass in the packaging industry through research and development.

Sustainability has been a major issue to Stoelzle for years now, and significant investments have been made in R&D, technologies and processes throughout all production and decoration sites in order to achieve important targets in the field of energy reduction and to boost eco-friendly processes and technologies. Therefore, participating in the ZeroCO2Glas project has been a great honour for Stoelzle.

R&D project ZeroCO2Glas

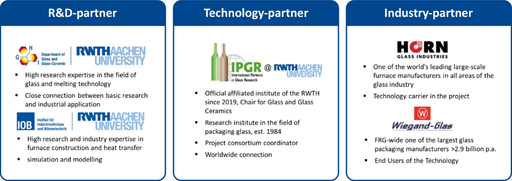

The project is funded by the German Ministry for Economy and Climate, BMWK, with a maximum of EUR 8.38 million and a total project volume of approximatively EUR 14.94 million. The consortium partners involved are:

The funding announcement refers to increasing energy efficiency, expanding renewable energies and reducing greenhouse gases significantly. In this respect, the ZeroCO2Glas project makes a significant contribution as it relates to the energy-intensive glass industry, where up to 85 percent of the energy required in the manufacturing process is used for the melting. The batch mixture that is brought into the furnace must be heated to a temperature of 1,450 to 1,650 degrees Celsius and converted into glass. In large furnaces, this is mainly done by natural gas-fired burners. ZeroCO2Glas focuses on the melting process, opening the possibility of saving a particularly large amount of energy and greenhouse gases.

The innovative melting technology is aimed to reduce energy consumption by 15 percent compared to conventional furnaces, and shall allow CO2-free glass melting. Energy savings will be achieved by using alternative and CO2-free raw materials, avoiding unnecessary humidification of the batch, as well as reducing the dwell time of the glass in the furnace due to a special melting process and the improved furnace design. The furnace will be set up in Aachen, Germany, as a hybrid furnace with hydrogen-oxy and natural gas-oxy firing, as well as electrical heating.

All approaches have already been tested on a laboratory scale, so the project represents the second stage of up-scaling.